LIGHT PROGRESS

DIRECT-H-K [eng]

gen-2021

Pag. 9/16

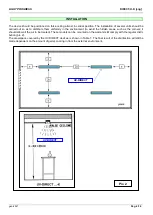

► UV-DIRECT-EL

In model

-EL

you get the possibility to remote control the functionality of UV tube.

Connected to the device there is a cable with 7 poles: a couple of poles carrying output signal to turn on LED indicating

the UV lamp

(when it’s lighting); another couple of poles triggers a voltage-free contact to be activated when a lamp-

stops working (alarm function: open contact if at least one lamp UV is not working); in addition, there are two input

wires to power the device (phase and neutral).

The faulty lamp alarm contact can be powered by max. 500mA of current and 24V of tension, and can be connected to

an electronic panel as "MASTER-

ST” control unit.

For this models see the numbering of the wires on the table below.

In the device

UV-DIRECT-

EL …

Multi-pole plug

and socket

Wire

Meaning

Black

wire for LED

terminal n°

1

Wire

n°1

1-

anode LED for synoptic

2-

cathode LED MASTER-ST......

Red

wire for LED

terminal n°

2

Wire

n°2

Power line 230V-50Hz - phase

terminal n°

3

Wire

n°3

3-

Line 230V-50Hz (Phase)

Power line 230V-50Hz - Neutral

terminal n°

4

Wire

n°4

4-

Line 230V-50Hz (Neutral)

Electrical ground

terminal n°

9

Wire

Y/G

Y/G- Ground terminal

Alarm board faulty tube

terminal n°

5

Wire

n°5

5-6-

open contact = faulty tube

(free contact without tension, max 500 mA-24V)

terminal n°

6

Wire

n°6

Model

-EL