LIGHT PROGRESS

FLOW-C-NX [Eng.]

Rev. 2 Oct -2020

Pag. 8/16

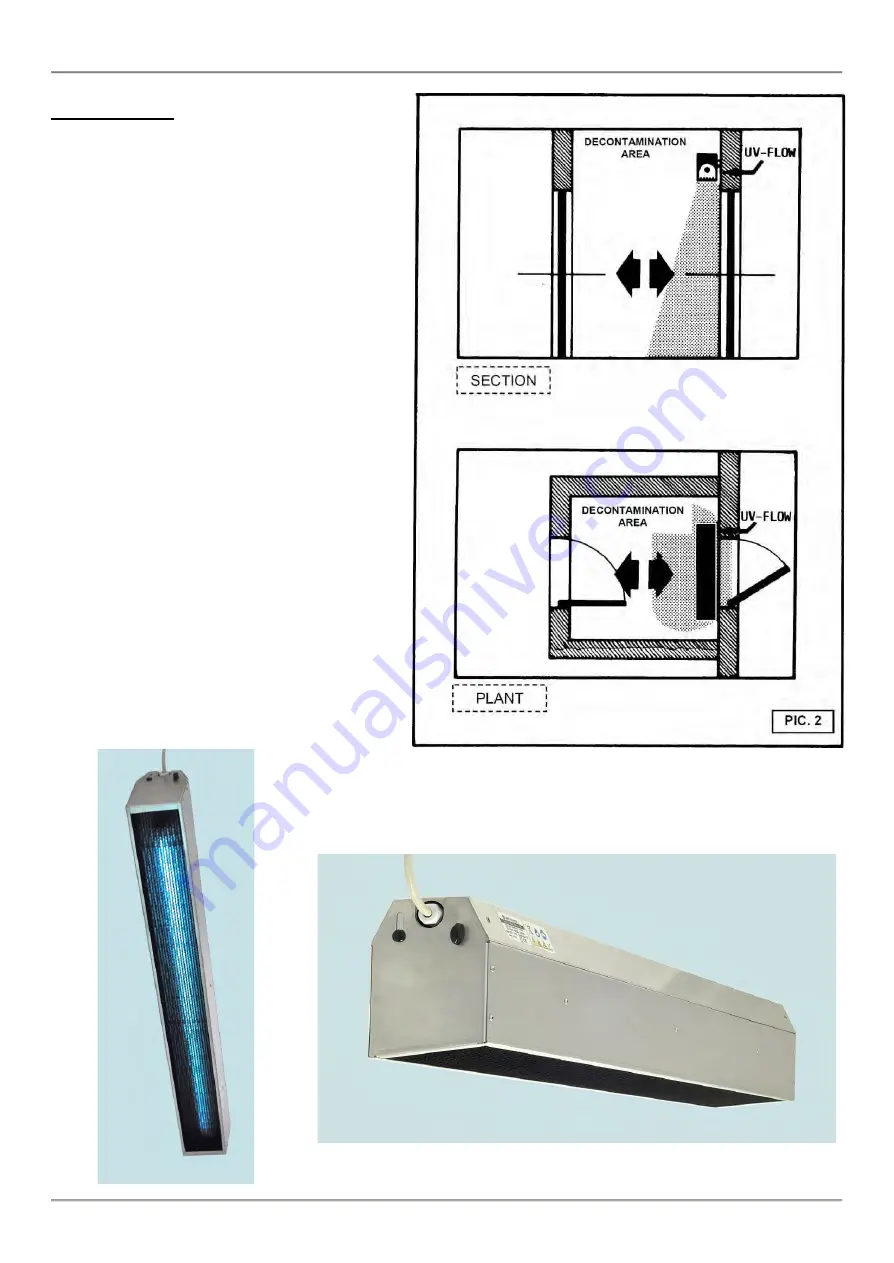

VERTICAL FLOW:

The device must be placed above the doors of the

controlled contamination room (clean room), with air

flow directed downwards. Use the two supplied

stainless-steel brackets, anchoring them to the wall

with expansion bolts (

8 to

10 mm.) or with self-

tapping screws.

This arrangement generates a vertical air flow which

produces barrier against germs (pic. 2).

For proper use you should create a decontamination

area between two adjoining rooms, to be kept under

microbiological and hygienic control. This zone

can be made simply by a double opening, door

and Avant-door system, just over the front door wide

and about 1.5 to 2 meters deep.

Of course, the doors should be normally closed

(preferably equipped with electrical or mechanical

locking, spring-return type). Normally, only one port

at a time must be opened and when one door is

opened, to allow entry of the decontamination area

the second door must stay closed; After the

entrance, the person will close the first door and, in

succession, will open the second closed door.

When a person is within the decontamination area the

infrared ray presence detector will switch off the UV-

FLOW, to protect personnel from UV irradiation; the

sensor will switch on the UV-FLOW again when the

person has left the area.

However, it is not required to switch off the UV-

FLOW if personnel wear UV-C ray protection

clothing, such as hats with visors, and stay within the

decontamination area only f o r the necessary time

of passage.