LIGHT PROGRESS

STICK-AL [eng]

Nov-2019

Pag. 7/16

WARNING!!!

To avoid exposition to UV-C rays please provide a total shielding of the modules, or automatic turning OFF disposals at

the entry doors in the environment treated. There must be no direct irradiation of the personnel.

To shield the devices you can use materials with opaque surfaces such as stainless steel or aluminum, but also trans-

parent materials such as glass or Lexan

®

; to have further information please contact us.

To improve safety we suggest you to add light signs or signboards to report the potential danger.

Remember to switch on the device ONLY IF there is a concrete shield and nobody will be irradiated by the UV-rays.

The indications given are indicative and not intended to be exhaustive. It's always advisable to check the compatibility

of the plant where the device must be inserted and the characteristics of the unit while respecting the laws and / or

regulations in the country of use. This verification, and the eventual preparation as may be necessary for the proper

use of the device , is always charged and under the full responsibility of the buyer. The company. disclaims any

responsibility for damage to property, persons or animals caused by the failed observation of the due liability.

ELECTRICAL CONNECTIONS

We suggest you to let a qualified electrician to install this device, following these instructions and electrical scheme,

and following the CE norms.

Before connecting the device to the electrical line, be sure that the label data are the same as the one on the supply

line; we remind you that the electrical supply of this device is 220-240V, 50/60Hz.

The connection required an interruption through a multipolar switch

Be sure that the electrical system fits the supply required by the device (please see the label).

The connection to the electrical line must be made by a 3 x 1 mm

2

supplied cable (See fig.).

Be sure that the device will be installed where it will fit with the existing environmental conditions

To avoid accidental exposition to UV-C rays, please dispose automatic lamps switch off in case of personnel

access. In any case provide warning lights and signals at the entry.

We suggest the use of hour-counters to know exactly the life of UV lamps and to remember when replace them

.

Protect the power supply cable from high temperature, sharp corners, water, oils

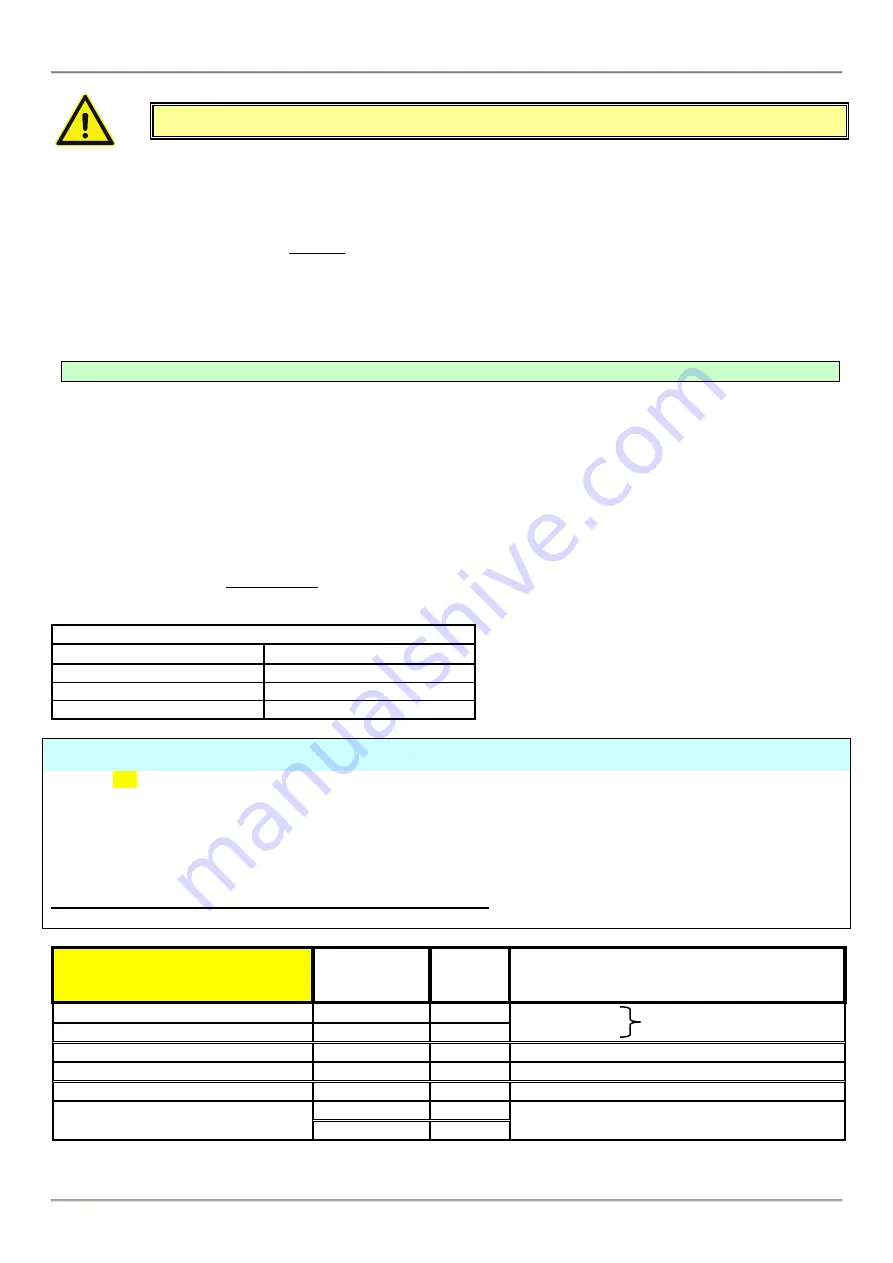

INPUT POWER LINE / PRESA DI INGRESSO LINEA

Colour / Colore

Connection / Connessione

Brown / Marrone

Phase / Fase

Blue / Blu

Neutral / Neutro

Yellow-Green / Giallo-verde

Ground / Terra

► UV-STICK-EL …..

In model

-EL

you get the possibility to remote control the functionality of UV lamp.

Connected to the device there is a cable with 7 poles: a couple of poles carrying output signal to turn on LED indicating

the UV lamp

(when it’s lighting); another couple of poles triggers a voltage-free contact to be activated when a lamp stops

working (alarm function: open contact if at least one lamp UV is not working); in addition, there are two input wires to

power the device (phase and neutral) + ground.

The faulty lamp alarm contact can be powered by max. 500mA of current and 24V of tension, and can be connected to

an electronic panel as "MASTER-

ST” control unit.

For this models see the numbering of the wires on the table below.

In the device

UV-STICK-ELnn-AL

Multi-pole

plug and

socket

Wire

Meaning

Black

wire for LED

terminal n°

1

Wire

n°1

1-

anode LED for synoptic

2-

cathode LED MASTER-ST.....

Red

wire for LED

terminal n°

2

Wire

n°2

Power line 230V-50Hz - phase

terminal n°

3

Wire

n°3

3-

Line 230V-50Hz (Phase)

Power line 230V-50Hz - Neutral

terminal n°

4

Wire

n°4

4-

Line 230V-50Hz (Neutral)

Electrical ground

terminal n°

9

Wire

Y/G

Y/G-

Ground terminal

Alarm board faulty lamp

terminal n°

5

Wire

n°5

5-6-

open contact = faulty lamp

(free contact without tension, max 500 mA-24V)

terminal n°

6

Wire

n°6