Document

: LH-A136-15-OB-OPM-DR-1.00

Page 23 of 37

© Lighthouse Technologies Ltd.

HK: T

+852 2192 1688

F

+852 2423 1092

info@lighthouse-tech.com www.lighthouse-tech.com

3.2

Electrical

The power distribution system used must provide adequate protection against excess line current and leakage

currents to earth.

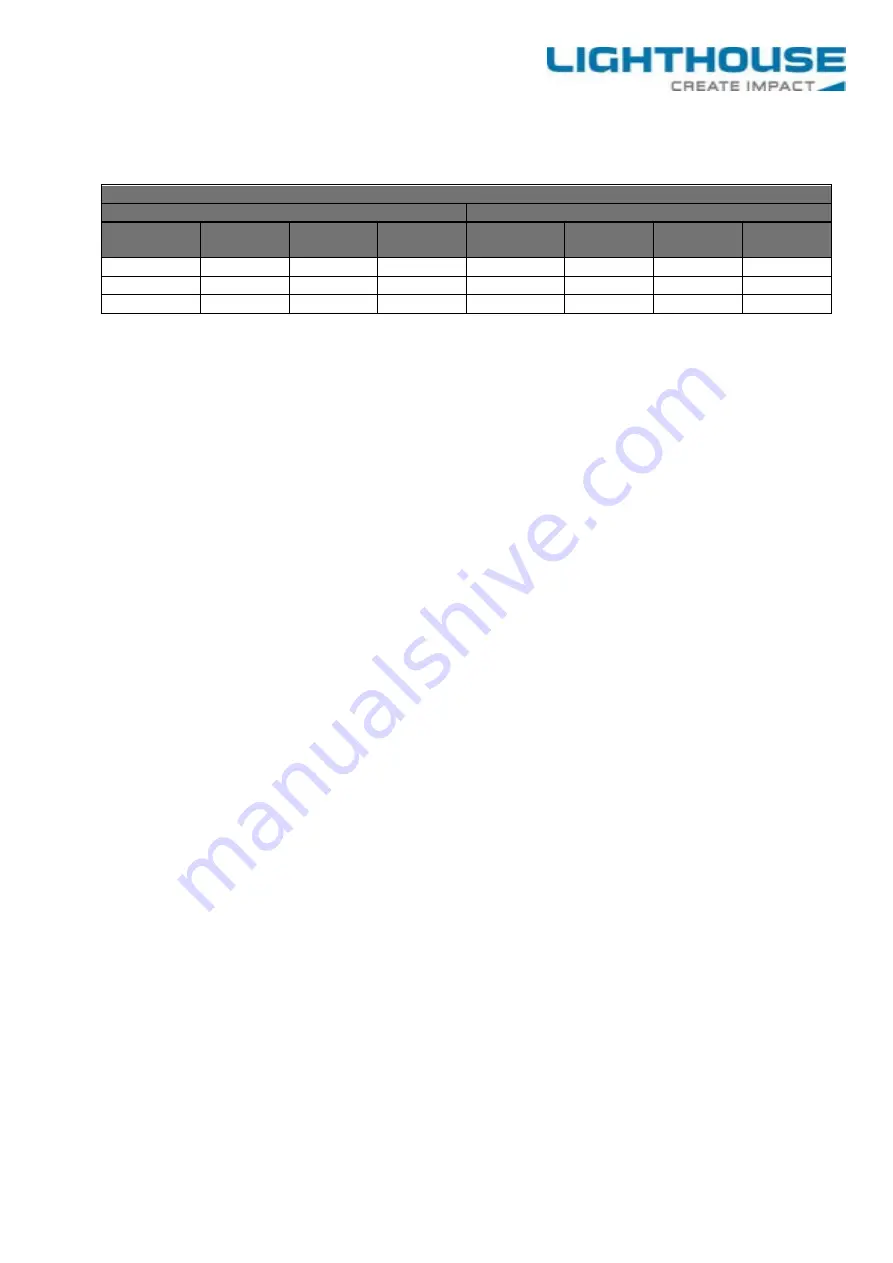

Electrical Characteristics for ONE A136-15-OB

At 100V AC Input

At 240V AC Input

Parameter

Unit

Rating

nom.

Max.

Parameter

Unit

Rating

nom.

Max.

Input current

A

12

30

Input current

A

5.00

12.5

Input freq.

Hz

50 – 60

65

Input freq.

Hz

50 – 60

65

Power

W

1200

3000

Power

W

1200

3000

3.2.1 Circuit Protection

Each section of the screen should be protected by a Circuit Breaker to protect against high fault currents, and a

Residual Current Device (RCD) to detect earth leakage currents.

3.2.2 Earth Leakage Considerations

Each panel of the system has earth leakage current contributions from ten switched-mode power supplies and one

SCHAFFNER/RFI filter. The total earth leakage current per panel can be up to 5.75mA at 240V. If a 30mA RCD is

used, then the maximum number of panels per section should be safely limited to 5.

3.2.3 Inrush-current and Over-current Considerations

The inrush current of the switched mode power supplies used to provide LED and logic power to each panel is

specified by the manufacturer as 97.5A at 115volts and 195A at 230volts for duration of 3ms. However, maximum

current in the steady-state for a panel is considerably less: 12.5A at 240 volts and 30A at 100 volts. The circuit

breaker used to control a section of the screen must be able to handle the short-term inrush current at switch-on,

without causing unnecessary disconnection of the supply, and be able to detect excess currents due to faults within

the equipment, during normal operation.

3.2.4 Earthing

Each panel is separately connected to the AC power distribution system’s earth through the appliance coupler. All

exposed panel metalwork (main frame) is also connected to this earth.

If the framework is earthed only through each panel (i.e. through the panel’s mounting bolts), there is a possibility of

electrical damage if a wiring fault occurs, or if an electrical discharge, such as lightning strike, hits the panels. Under

these circumstances, the current discharge path will be through the panel to earth rather than through the framework

to earth. When permanently installed on a metal framework, the framework itself should be directly connected to

earth also.

3.2.5 EMC Statement

Installations should be located at least 30 meters from other sensitive systems or installations and if situated in close

proximity to a roadway it may create interference to vehicle radio communications.

3.2.6 FCC Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

*Note: Modifications not authorized by the manufacturer may void users authority to operate this device.