5. Operation Instruction

5.1 Display Indication

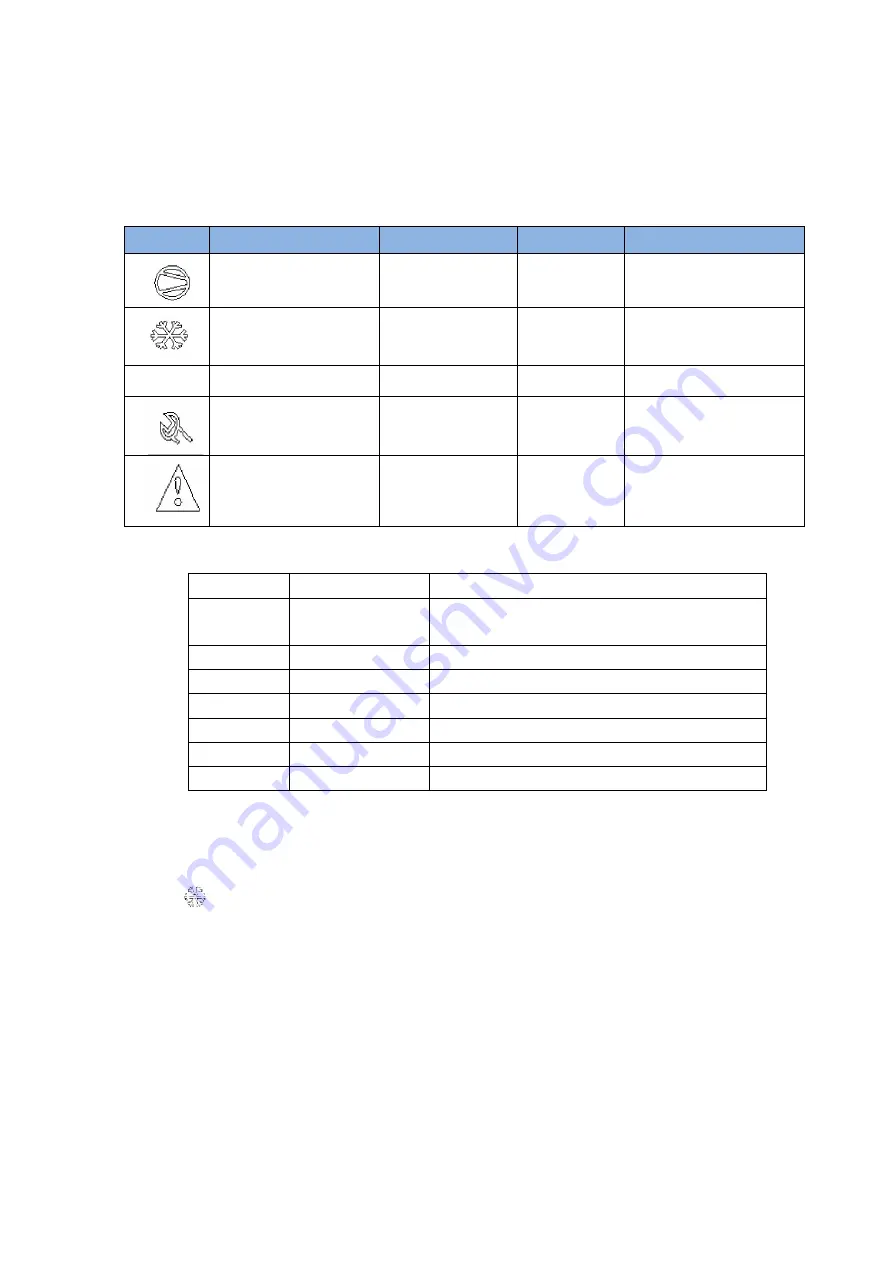

Display Sign Description

Icon

Function

On

Off

Blinking

Load

On

Off

Being delay load output

Cooling TEMP. Setting

In the setting state

----

----

HACCP

Heating TEMP. Setting

In the setting state

----

----

Repairing

Faulty

No fault

----

Warning

Warning

No warning

----

Panel Digit Indication

Four red digits display the measured temperature and warning code.

No.

Display Code

Warning Information

1

E01

Room temperature sensor fault

( short circuit or open circuit )

2

Hi

Temperature exceeds the MAX value

3

Lo

Temperature exceeds the MIN value

4

EE

Data access error

5

Err

Password error

6

iA

External warning

7

UnL

Restore the default password ”1111”

6.2 Keypad Operation

6.2.1 Set coo/heat temperature

Keeping

【

S

】

pressed for 3 seconds to

enter temperature setting mode. The indicator

or

“

HACCP

”

is on, and the digital shows the set temperature. Press key

【

▲

】

or

【

▼

】

to change the set temperature ( Keeping

【

▲

】

or

【

▼

】

pressed, it will be adjusted

quickly.). Press

【

S

】

, the set temperature will be saved and leave the setting mode. Or do not

press any key for 30 seconds; the device will leave the set mode without saving the set data.

6.2.2 Set system parameters

Enter Into System Parameter Setting Mode

Use the password to enter into the parameter setting mode, the factory password is “1111”.

Keep

【

P

】

pressed for 3 seconds to enter the mode. The digital displays

『

---0

』

, then press

【

▼

】

to the digit of the password, press

【

▲

】

to the value of the digit, press

【

S

】

to

confirm. If the password is wrong, it will shows

『

Err

』

, and returns to the measuring

temperature states after the buzzer beeping 3 times. If the password is right, the buzzer beeps

Summary of Contents for ZL-660A-R

Page 7: ......