There are following ways for the external warning input, when the condition meets, the

device will warn:

Normal On: If close, warning starts.

Normal Off: If open, warning starts.

Lock: when the external warning input signal disappears, system keeps warning, until

pressing the

【

P

】

key to stop the warning.

Unlock: when the external warning input signal disappears, warning stops.

7.8 Temperature Calibration Function

When there is tolerance between the measured temperature and real temperature, set

parameter U20 and U21 to calibrate. The calibration range is ±9.9

℃

. When setting the

parameter, the step is 0.1

℃

for every key press. Keep the key pressed, the set data will

increase/decrease continuously and quickly.

7.9 Restore the Default Parameters and Password

Keep

【

P

】

and

【

▲

】

keys pressed for 5 seconds, the device displays “UnL”, press

【

▼

】

twice,

buzzer sounds, system auto restores the default parameters and password“1111”.

8. Controller Installation

8.1 Warning

Avoid installing the device in the following environment:

● Relative humidity is greater than 90%, or possibly dewing.

● Strong vibration.

● Possibility be dropped, or within fog.

● Exposed to eroding and polluting gases (such as: air containing sulfur and ammonia, salty

fog, smoky mist) to prevent erosion and oxidation.

● Ambient containing explosive or inflammable materials/gases.

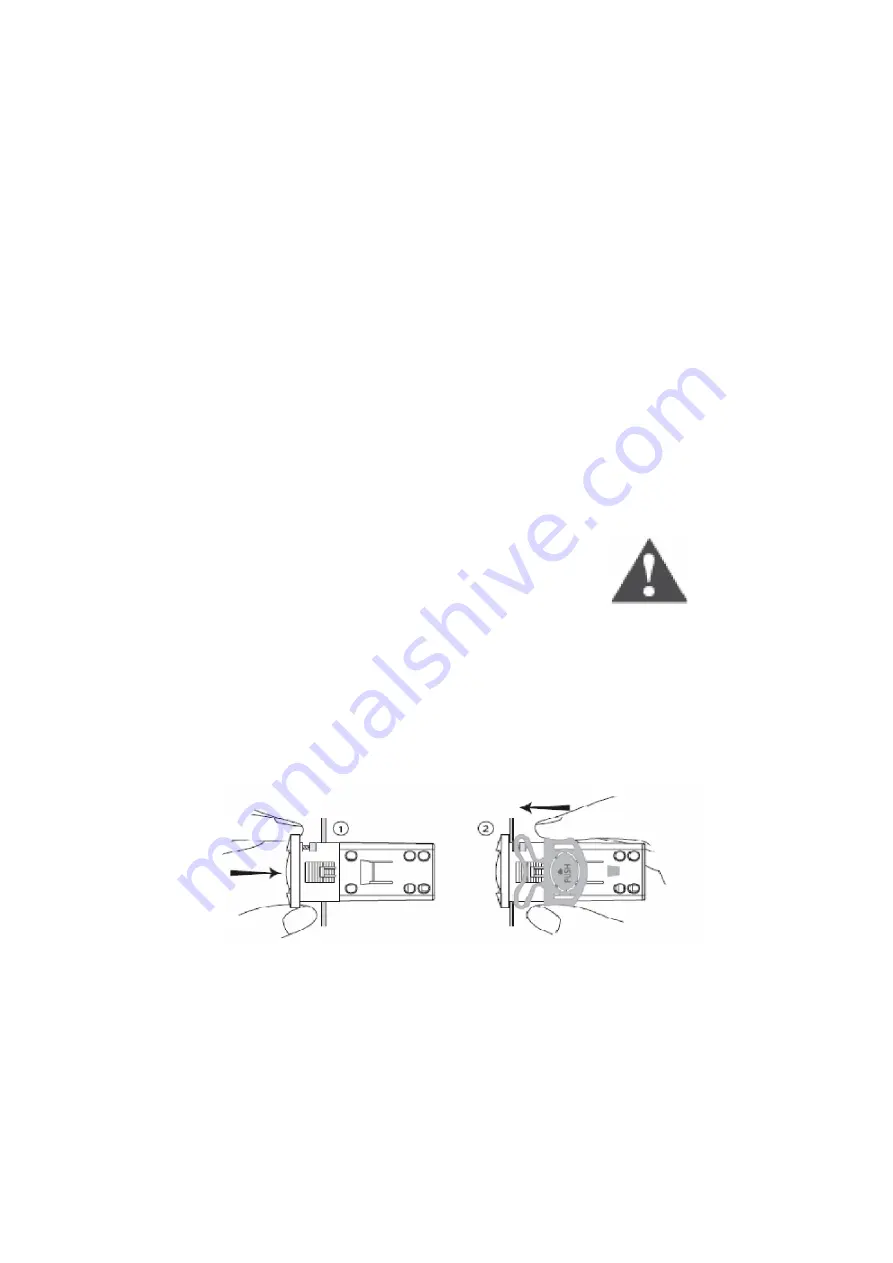

8.2 Installation Procedure

Insert the controller into hole (step one) Slide the bracket to fix the device (step two)

9. Electrical Connection

Warning

● Electrical wiring must be manipulated by certified electrician.

● Wrong power supply may damage the device and system seriously.

● Try with effort to layout the sensors and switches line apart from inductive load lines and

Summary of Contents for ZL-660A-R

Page 7: ......