If the flame shape has deteriorated or/and has become smoky this could be due to a worn nozzle or it could

be that the oil supply or spillback pressure has been adjusted too low. Check nozzle condition, supply and

spillback oil pressures and oil filter cleanliness during every service or if the flame is not burning cleanly.

The nozzles are designed to be “non drip” the LC 21 and LC36 have an inbuilt positive nozzle shut off system

to ensure no after drip. Sometimes nozzle drip can be caused by air in the oil pipe work, if this is the case

ensure that all of the air is expelled from the oil pipe work before re firing the burner.

The burners are fitted with a check valve in the return pipe work this should be checked for debris and correct

operation.

Always use calibrated ‘U’ tubes, pressure gauges when commissioning on gas, you will also require a smoke

tester when commissioning on the burner on oil. Oil spillback pressure gauges are fitted to the burner as

standard.

The following servicing procedures should be employed: -

6

7

5

4

1

3

2

1. Sight Glass Assembly/Access Door

2. Oil Flow to Lance connections

3. Oil Return From Lance connections

4. Oil Lance assembly

5. Gas Manifold

6. Diffuser Plate

7. Blast Tube

Summary of Contents for LC Series

Page 3: ...Section 1 Legal statements and Disclaimers Burner assembly area ...

Page 7: ...Section 2 Burner Technical Data Gas flame firing at 12 300 000 btu hr ...

Page 9: ...Section 3 Component Information General assembled burner ...

Page 11: ...Section 4 Gas Manifold assembly Split gas head assembly ...

Page 16: ...Section 5 Oil Gun assembly Oil nozzle and lance assembly ...

Page 19: ...Section 6 Electrode settings Pilot injector and ignition setup ...

Page 22: ...Section 7 Burner Installation Limpsfield LC9 dual fuel burners on Hurst boilers ...

Page 24: ...Sample Typical fire tube installation ...

Page 25: ...Typical water tube installation ...

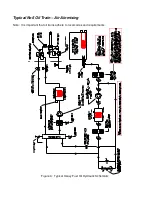

Page 29: ...Section 8 Typical Gas control Train 2 gas control train assembled ...

Page 32: ...Section 9 Typical Oil Train Assembled oil pump with filter ...

Page 36: ...Section 10 General start up procedure ...

Page 43: ...Section 11 Service Recommendations ...

Page 47: ...Section 12 General Burner Servicing Procedure ...

Page 52: ...Section 13 Fault Finding ...