BLD5/10 User Manual

BLDC50/100

User Manual

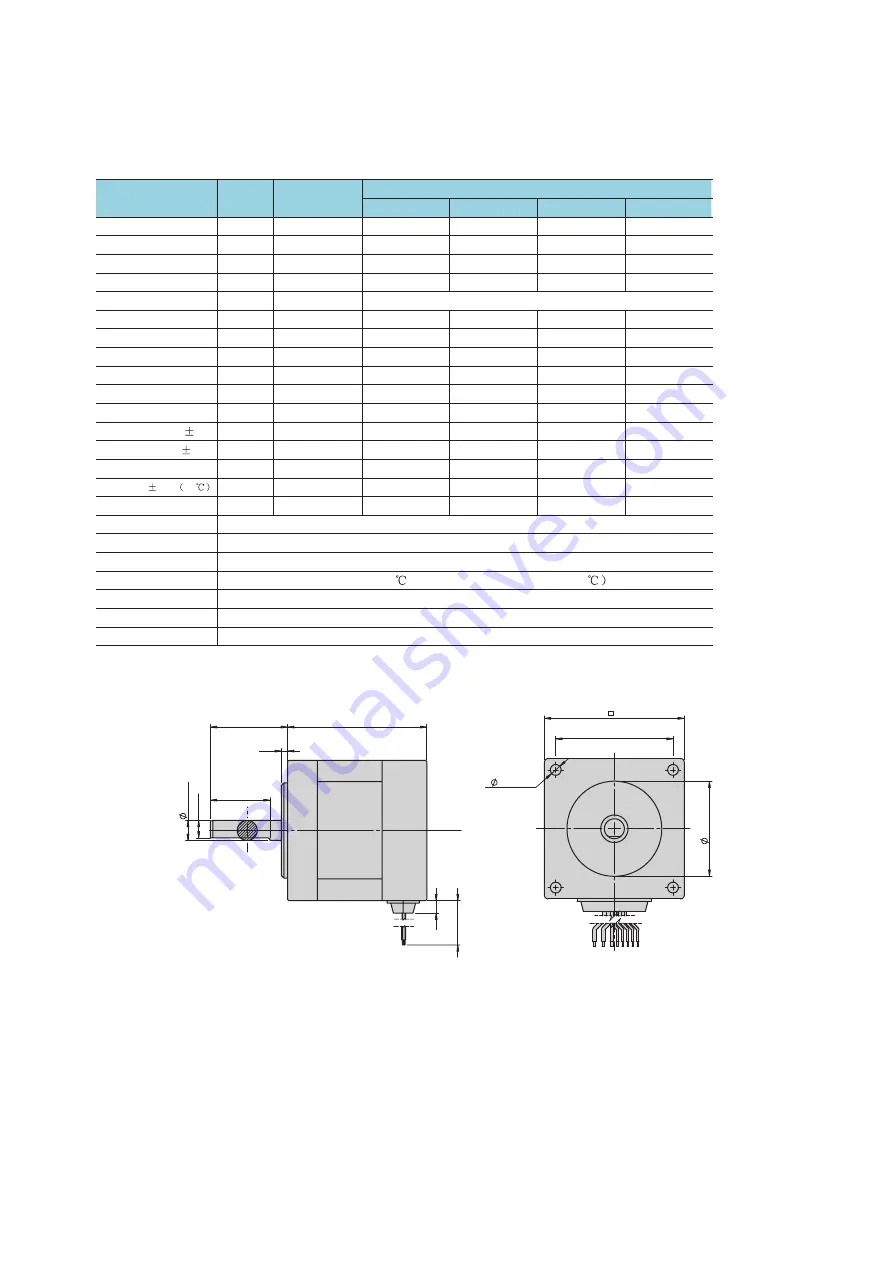

NEMA 34

BLDC MOTOR

Technical Speci ication

Dimensions

Symbols

Units

Type

BL

34E21-01

BL34E21-02 BL34E27-02 BL34E34-01

mm

57

57

57

57

Length

L

mm

50

50

67

84

Input voltage

Un

VDC

24

48

48

48

Rated power

Pn

W

100

100

200

300

Phase number

3

P

Rated speed

Nn

RPM

4000

4000

4000

4000

Max. speed

Np

RPM

4500

4500

4500

4500

Rated torque

T

mNm

240

240

480

720

Max. torque

Tmax

mNm

480

5

300

2.43

600

1440

Rated current

I

Arms

5.06

10.12

7.49

Max. current

Imax

Arms

10

4.86

14.98

Voltage constant 5%

Vrms/Krpm

3.44

7.3

7.2

7.3

Torque constant 5%

Nm/Arms

0.048

0.099

0.095

0.096

Moment of inertia

10^-4kgm^2

0.38

0.38

0.74

1.08

Resistance 10% 25

R

Ω

0.18

0.71

0.27

0.20

Inductance

L

mH

0.34

1.35

0.70

0.47

Sensor

Hall

Ins.class

E

Protective rating

IP40

Operating temperature

0~+50 (storage temperature -20~+60

Operating RH

85% RH or below (noncondensing)

Operating environment

Outdoor (no direct sunlight), no corrosive gas, no fl

ammable gas, no oil mist, no dust

Altitude

1000m or below

1 2 345678

5.5

73

h7

80

-

±0.1

2-

69.58

±0.1

0.0

12

±1

11

2

5

±0.1

2

14.4

±0.2

0

3

0

±0.

05

3

0

0

L

±2

0

±1

12

-

±

0.2

0.0

12

0

Lin Engineering

BLDC 50/100 Driver Manual

Page 26

Version 1.0

01/29/2020