IS 400 ECN 4176

Page 5 of 11

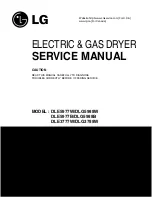

Power Ratings

Model

Power (kW)

Supply 1N~+E(A) 230V

Supply 3N~+E (A) 400V

DF33

3.0

13.0

N/A

DF36

6.0

26.0

L1 13 L2 13 L3 N/A

DF39

9.0

39.0

L1 13 L2 13 L3 13

DF46

6.0

26.0

L1 13 l2 13 l3 N/A

DF49

9.0

39.0

L1 13 L2 13 L3 13

DF66

6.0

2 x 13.0

N/A

DF66/ST

6.0

26.0

L1 13 L2 13 L3 N/A

DF612

12.0

2 x 26.0

L1 13 L2 13 L3 N/A

DF618

18.0

2 x 39.0

L1 13 L2 13 L3 13

J6

6.0

26.0

L1 13 L2 13 L3 N/A

J9

9.0

39.0

L1 13 L2 13 L3 13

J12

12.0

2 x 26.0

2 x L1 13 2xL2 13 2xL3 N/A

J18

18.0

2 x 39.0

2 x L1 13 2xL2 13 2xL3 13

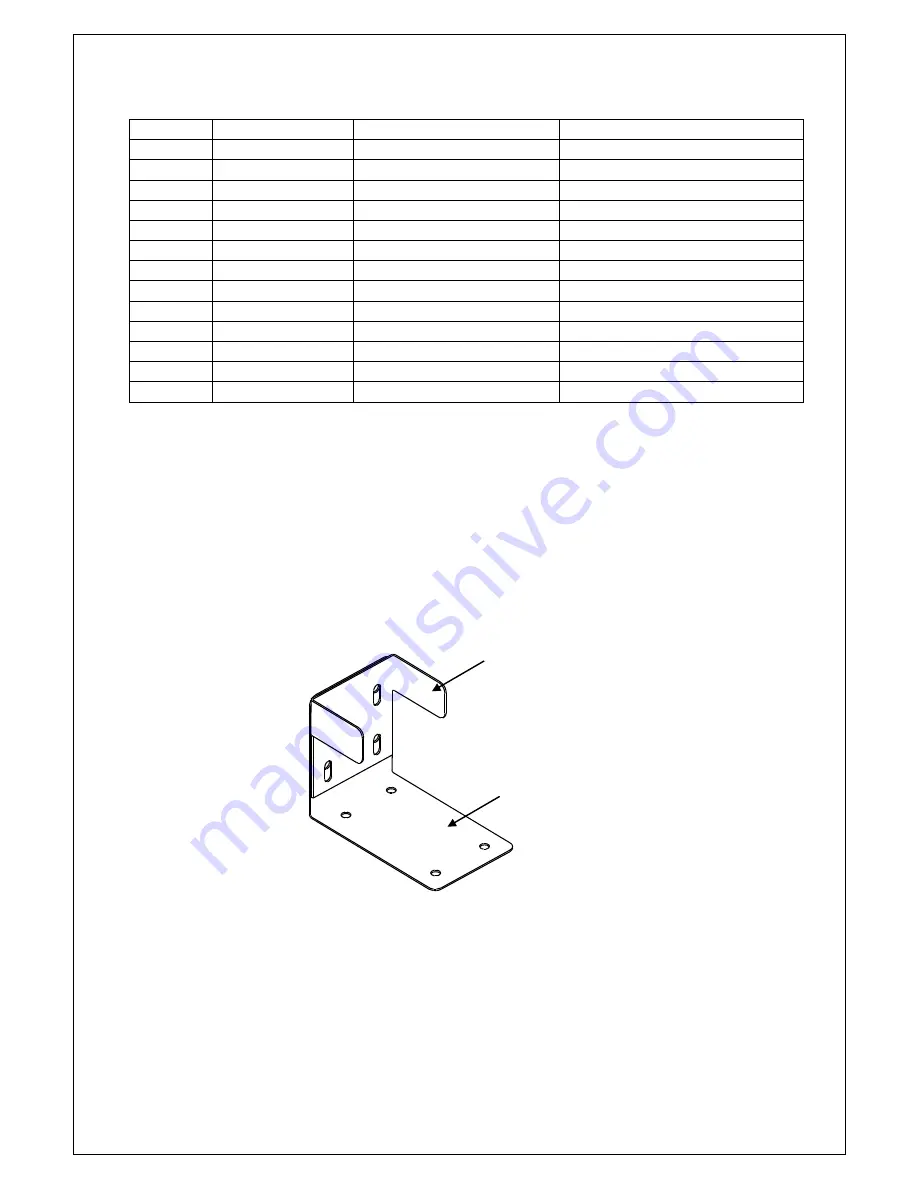

On J fryers, assemble the nuts provided to each foot, add a washer and fit the feet

to the holes provided in the base.

It is essential that the stability kit provided is used with J6 and J9 fryers. Bolt the

base plate to the floor, attach the stability bracket using the bolts and washers

provided and push the fryer into position, ensuring that the wings on the bracket

locate into the slots at the base of the fryer back.

Bolt to floor

Locate wings into slots

In fryer back