IS355 ECN3592

10

DRAINAGE

Always allow the oil to cool to a maximum 55

o

C before draining.

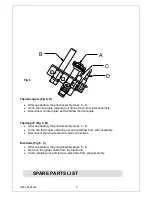

Remove the blanking nut from the front of the unit

(Fig 3, 5).

Fit the drain pipe,

which has a stowage clip under the lid, and place a suitable receptacle under the

pipe outlet. Lift the safety catch

(Fig 3, 7)

and operate the tap by moving the handle

(Fig 3, 6)

to the right to drain. Remove the pipe and fit into its storage position in the

lid. Replace the blanking nut and close the tap before refilling the tank.

Take care when draining the oil that the drain bucket is not filled so full that it is

difficult to handle.

Excess oil remaining in the base of the tank can be mopped up using kitchen paper.

CLEANING

Note: Clean the appliance with hot water and a mild detergent

– do not use abrasives. In extreme

conditions a branded cleanser such as “Carb „n‟ Off ” makes cleaning easier after an overnight

application.

Isolate the appliance from the gas supply.

Allow the oil to cool to a maximum 55

o

C.

Drain as per above instructions.

Wash the tank and the top surface of the fryer body.

Clean the drain tube assembly, using a tube or flue brush suitable for 15mm tube,

with the drain valve in the open position. Clean by inserting the brush into both the

inlet and outlet of the drain.

Wash all parts thoroughly.

Ensure all parts are thoroughly rinsed and dried. To ensure there is no water left in

the drain tube, flush thoroughly with a small amount of clean cooking oil.

Re-assemble by reversing the above procedure.

OPERATOR PRECAUTIONS

Never leave the unit unsupervised whilst frying.

Always drain food of excess moisture before frying, never put water into the oil.

Overheating the oil may lead to hazardous circumstances.

Ensure oil is always maintained at the level indicated (H-High, L-Low) to avoid

risk of hazardous circumstances.

Never use flammable cleaning agents on the appliance.

Under no circumstances should replenishment of the oil when the appliance is

hot.

NOTES ON FRYING MEDIA

Good quality vegetable oil is recommended. Animal fat may be used - but must always be

melted first. Animal fat has a lower smoke and fire temperature than vegetable oil and

taste is transferred when cooking with it (e.g. onions fried in animal fat will taint other foods

i.e. fish which may follow). This does not occur when cooking with vegetable oil.

The life expectancy of oils and cooking fats will be lengthened if they are filtered regularly -

food particles not removed turn rancid and reduce oil/fat quality.

Vegetable oils and animal fat are incompatible - e.g. if sausages containing a lot of animal

fat are fried in vegetable oil, the oil will tend to "glue" and spoil.

Summary of Contents for Silverlink 600 DC04

Page 20: ...IS355 ECN3592 Notes...