IS355 ECN3592

9

LIGHTING SEQUENCE

Please ensure that the gas isolation valve for the appliance is turned to the open

position before attempting to light this unit.

1.

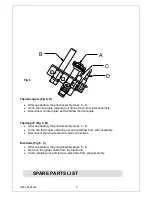

Ensure that the thermostat control knob

(Fig 3, 1)

is in the OFF position.

2.

Ensure the gas valve control knob

(Fig 3, 2)

is in the off position.

3.

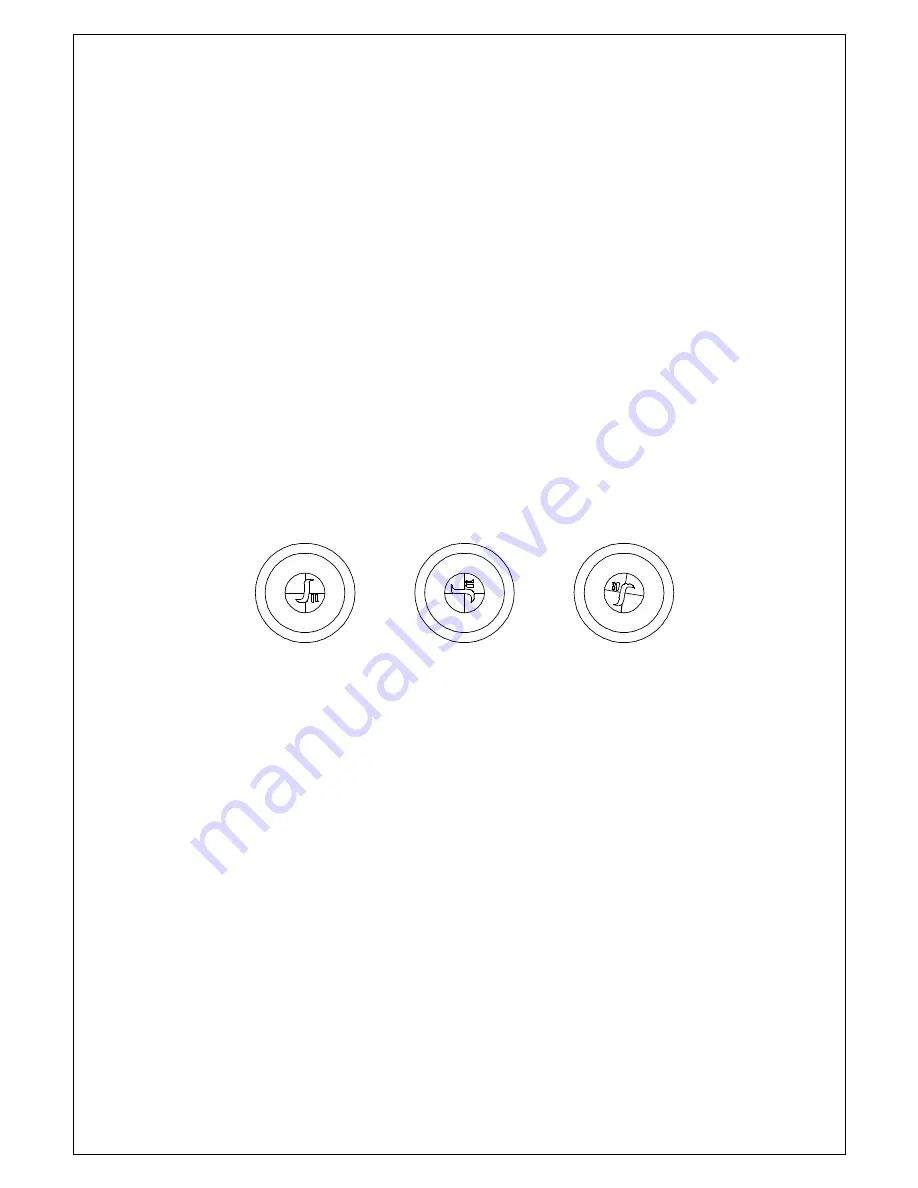

(Fig 4, A)

Push in and turn anti-clockwise to the Pilot position

(Fig 4, B).

The knob will

now depress further.

4.

Keeping the pilot control knob depressed, press the piezo ignition button

(Fig 3, 3).

5.

Ensure the pilot flame is alight, a blue flame can be seen when looking into the pilot

viewing window

(Fig 3, 4).

Hold the pilot control knob in for 20 seconds to establish the

pilot flame.

6.

When the pilot is lit, release the pilot control knob and continue to turn fully anti-

clockwise to the ON position

(Fig 4, C)

.

7.

If the pilot flame fails to remain lit, return the pilot control knob to the off position and

repeat the process allowing a short period of time for the control to reset.

8.

To operate the main burner, turn the thermostat control knob

(Fig 3, 1)

to the required

temperature setting.

O

F

F

PILOT

O

N

OF

F

P

IL

O

T

ON

O

F

F

PIL

OT

O

N

A

B

C

Fig 4.

STANDBY

Once the pilot is lit, the appliance may be left on standby by leaving the pilot control knob in

the pilot ignition position.

(Fig 4, B)

. When in this position the appliance cannot be

operated from the thermostat control knob. To re ignite the main burners turn the pilot

control knob anti-clockwise to the burner position,

(Fig 4, C)

, and operate the control

thermostat as normal.

Note: Should the safety cutout thermostat operate during normal use the unit will

shut down. To re-light the unit allow the oil to cool to a temperature below 200

o

C.

Re-set the safety thermostat by depressing the red re-set button. (Fig 3, 8).

SHUT DOWN

When the appliance is not required, turn the thermostat fully anti-clockwise, which will shut

down the main burner but leave the pilot lit ready for when the appliance is next required.

To turn the unit off completely, turn the thermostat fully anti-clockwise and the pilot knob

fully clockwise.

Summary of Contents for Silverlink 600 DC04

Page 20: ...IS355 ECN3592 Notes...