IS 358 ECN 3592

10

STANDBY

Once the pilot is lit the appliance may be left on standby by leaving the pilot control knob in the pilot

ignition position.

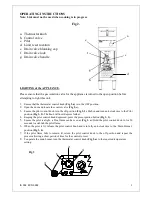

(Fig 3, 2)

. When in this position the appliance cannot be operated from the thermostat

control knob. To re ignite the main burners turn the pilot control knob anti-clockwise to the burner position,

(Fig 3, 4)

, and operate the control thermostat as normal.

Note: Should the safety cut-out thermostat operate during normal use the unit will shut down. To re-

light the unit allow the oil to cooled to a temperature below 200

o

C. Re-set the safety thermostat by

depressing the red re-set button. (see fig 2)

SHUT DOWN of the APPLIANCE.

1)

When the appliance is not required, turn the thermostat fully anti-clockwise which will shut down the

main burner but leave the pilot lit ready for when the appliance is next required.

2)

To turn the unit off completely, turn the thermostat fully anti-clockwise and the pilot knob fully

clockwise.

PREPARATION FOR USE

1)

Ensure that the drain valve is closed.

2)

Fill the tank with water and a little mild detergent.

Turn the unit "ON" (see Operating Instructions) and allow the water to boil for a short time.

3)

Switch off and drain off the water.

Rinse the tank and dry thoroughly.

Ensure that the drain pipe and tap are dried thoroughly.

4)

Run a small quantity of oil across the base of the tank and allow to drain to waste.

This will remove any residual water and provide the base of the tank with a coating of oil.

5)

Close the drain valve

DRAINAGE

1)

Always allow the oil to cool to a maximum 55

o

C before draining.

2)

Remove the blanking nut,

(Fig 2, e)

, from the front of the unit. Fit the pipe supplied and place a suitable

receptacle under the pipe outlet. Lift the drain valve handle lock,

(Fig 2, f)

, to allow operation of the

drain valve.

3)

Move the drain valve handle,

(Fig 2, g)

, forward and upward to drain. Close the valve, remove the pipe

and replace the blanking nut. Ensure that the drain valve handle lock has dropped into position before

refilling the tank.

4)

Take care when draining the oil that the drain bucket is not filled so full that it is difficult to handle.

5)

Excess oil remaining in the base of the tank can be mopped up using kitchen paper

CLEANING INSTRUCTIONS

Note: Clean the appliance with hot water and a mild detergent do not use abrasives. In extreme conditions a

branded cleanser such as “Carb „n‟ off ” makes cleaning easier after an overnight application.

1)

Isolate the appliance from the gas supply.

2)

Allow the oil to cool to a maximum 55

o

C.

3)

Drain as per above instructions.

4)

Wash the tank and the top surface of the fryer body.

5)

Clean the drain tube assembly, using a tube or flue brush suitable for 15mm tube, with the drain valve in

the open position. Clean by inserting the brush into both the inlet and outlet of the drain.

6)

Wash all parts thoroughly.

7)

Ensure all parts are thoroughly rinsed and dried. To ensure there is no water left in the drain tube, flush

thoroughly with a small amount of clean cooking oil.

8)

Re-assemble by reversing the above procedure.