14

FAULT FINDING

Explanation of the Control System

The gas circuit in this fryer is operated by two separate millivolt systems.

The first consists of an interrupted thermocouple, the pilot burner(s) and the gas control.

Heat from the pilot flame acting on the thermocouple generates a 15-30 mV electrical potential.

This millivolt system connected to the gas control operates the first solenoid that allows gas to the

pilot burner. The over temperature stat is included in this system which operates via the interrupted

thermocouple.

The first solenoid operates as the safety device which shuts down in the event of a thermocouple

failure or if the over temperature stat goes open circuit.

The secondary millivolt system consists of a thermopile acting through the gas control via the control

thermostat.

Heat from the pilot flame acting on the thermopile generates a 500-700 mV electrical potential.

This millivolt system connected to the gas control operates the secondary solenoid that passes gas to

the main burners.

The system is interrupted by the control thermostat as it cycles, thereby opening and closing the gas

supply to the main burners.

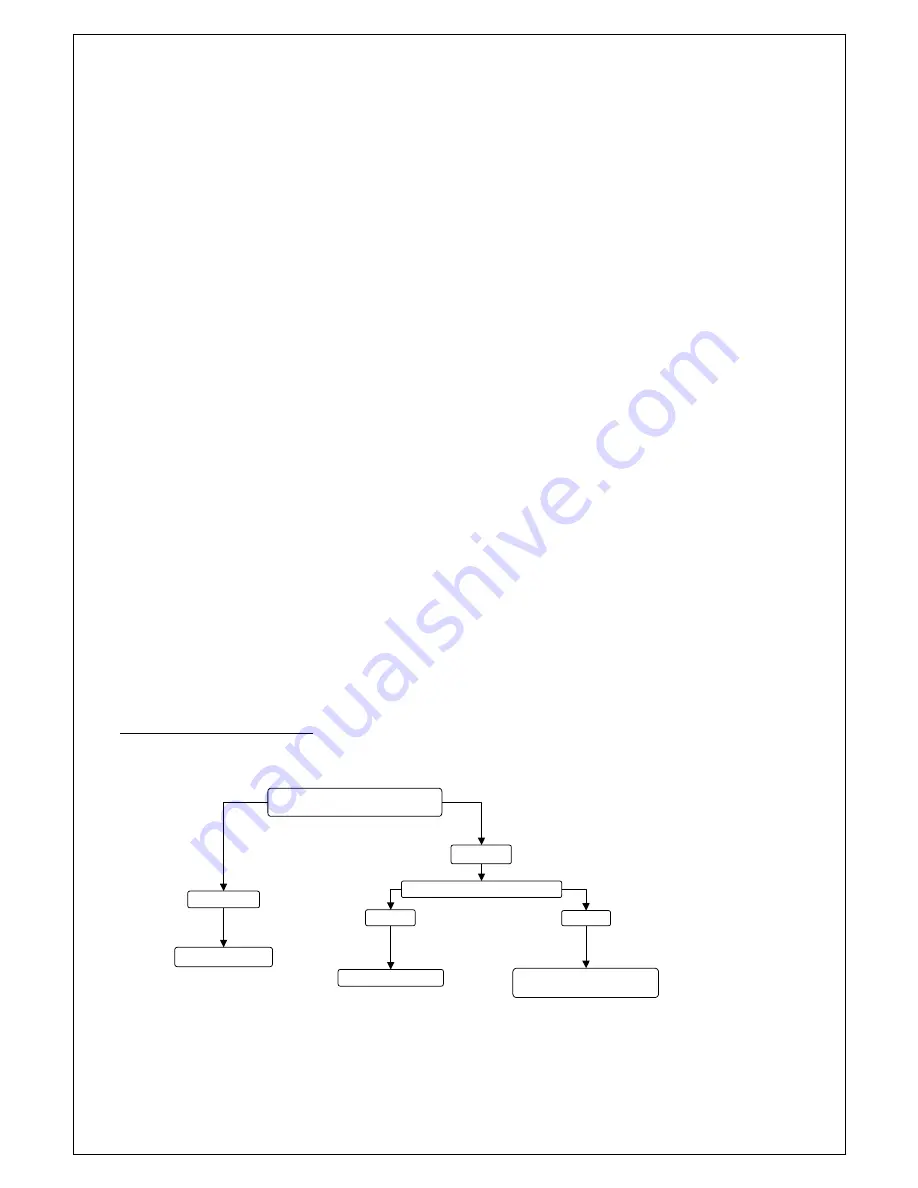

The following trouble shooting flow charts are designed to give assistance on the most probable

cause of failure of the gas circuit.

Use the step by step instructions to quickly pinpoint problems and the advice to help in taking the

appropriate action to rectify them.

Piezo Igniter not sparking.

Is there a short in the High Tension

Lead.

Replace Electrode.

Yes.

If no spark is generated at all,

replace Piezo Ignitor.

No.

Has Electrode Insulator Fractured.

No

Yes.

Replace Lead.