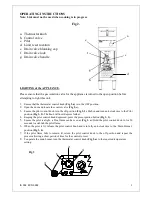

IS 358 ECN 3592

4

INSTALLATION INSTRUCTIONS.

Before commencing installation of the appliance please take time to read the following

installation instructions carefully.

Parts protected by the manufacturer are not to be adjusted by the installer or user.

Unit : J5 & J10.

All appliances should be installed in accordance with BS 6173:1982, Code of practice for installation of gas

catering appliances, taking into account the Gas Safety Regulations 1984 as amended by the Gas Safety

(Installation and Use)(Amendment) Regulations 1990 and the Health and Safety at Work Act 1974.

It is mandatory that all appliances are installed and commissioned by a qualified and competent GAS SAFE

registered gas fitter.

WARNING : Installation, service or repair of this appliance by non-GAS SAFE registered personnel

will invalidate its warranty.

VENTILATION

The area in which this equipment is to be installed should have sufficient fixed ventilation to comply with

the requirements of Approved Document J in the 1985 Building Regulations. It is recommended that a

minimum Area of 450mm

2

per 1kWh (3400Btu/hr) of total heat input must be allowed. Particular attention

should be paid to the low level ventilation to ensure that the appliance has a good supply of clean, fresh air.

INSTALLATION POSITION.

To ensure a free flow of air around and behind the appliance, clear space of at least 100mm must be left at

the rear between flue and the wall and to either side of the appliance or bank of appliances. There should be

a minimum clearance of 750mm between the top of the appliance and any overlying shelf or ceiling.

Any partitions, walls or kitchen furniture in close proximity should be of non-combustible materials.

Installation should allow for a sufficient flow of fresh air for combustion air supply.

It is recommended that this appliance is sited under an extraction canopy for the removal of combustion

products.

INSTALLATION COMMISSIONING.

To ensure a full understanding of the correct operation of the appliance the following commissioning checks

must be carried out before the appliance is handed over for use.

All operators must know how to light, safely operate and shutdown the appliance.

Although all Lincat fryers are operationally checked during manufacture, commissioning shall include an

operational check of all controls and a calibration check on the thermostat. This is carried out by filling the

fryer to the correct level which is indicated on the batter plate, then setting the thermostat to 180

C

The oil temperature should be checked once the main burner has cut-out for the second time. If necessary

calibration of the thermostat should be made as per the instructions fou

nd under the “Servicing” section.

GAS SUPPLY & CONNECTION

Check that the gas supply corresponds to that specified on the data plate.

Connection is via a 1/2" bspt male thread on the back of the unit. If connection to the supply pipe is via a

flexible hose, ensure that the hose used is suitable for commercial catering appliances. The supply hose

should be periodically examined and replaced as necessary.