B-4

OPERATION

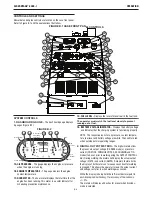

3. CROSSLINC INDICATOR LIGHT -

When a CrossLinc

enabled device is connected with the machine using the stan-

dard weld power cable and the device's sense lead is attached

to the work piece, the CrossLinc light will automatically illumi-

nate on both the machine and the device. No additional pairing

of the machine to the device is needed. This light indicates the

CrossLinc connection is active and that control of the voltage

and current can be made at the device.

4. OUTPUT CONTROL -

The OUTPUT CONTROL knob is

used to preset the output voltage or current as displayed on the

5. WELD TERMINALS ON SWITCH -

Output is enabled

when in the ON position. Output is remotely controlled when in

the REMOTE position. This control is not active in ArcLink

®

modes.

6. ARC CONTROL -

The ARC CONTROL knob is active in the

CC-STICK, DOWNHILL PIPE, and CV-WIRE modes, and has dif-

ferent functions in these modes. This control is not active in the

TOUCH START TIG, ARC GOUGING, or ArcLink modes.

CC-STICK mode:

In this mode, the ARC CONTROL knob sets the

short circuit current (arc force) during stick welding. Increasing

the number from -10 (Soft) to +10 (Crisp) increases the short

circuit current and prevents sticking of the electrode to the plate

while welding.

This can also increase spatter. It is recommended that the ARC

CONTROL be set to the minimum number without electrode

sticking. Start with a setting at 0.

DOWNHILL PIPE mode:

In this mode, the ARC CONTROL knob

sets the short circuit current (arc force) during stick welding to

adjust for a soft or a more forceful digging arc (Crisp).

Increasing the number from -10 (Soft) to +10 (Crisp) increases

the short circuit current which results in a more forceful digging

arc. Typically a forceful digging arc is preferred for root and hot

weld puddle control and deposition (“stacking” of iron) are key

to fast travel speeds. It is recommended that the ARC CONTROL

be set initially at 0.

CV-WIRE mode:

In this mode, the ARC CONTROL knob changes

the inductance ("pinch") of the current. By adjusting the pinch,

the the rate of current rise will change when the electrode short

circuits to the work.

Increasing the pinch from -10 to +10 may reduce spatter, while

7. WELD MODE SELECTOR SWITCH

Provides six selectable welding modes:

CV-WIRE

DOWNHILL PIPE

CC-STICK

TOUCH START TIG

ARC GOUGING

ARCLINK

8. 42V / 120V WIRE FEEDER VOLTAGE SWITCH

Toggles output of 14-pin connector to voltage requirement of

wire feeder. (Located above 14-pin connector.)

9. 5-PIN CONNECTOR

- For attaching an ArcLink

®

wire

feeder control cable.

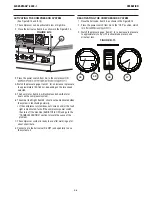

10. RUN / STOP / IDLE SWITCH -

Toggling the switch to

the RUN position energizes the fuel solenoid for approximately

30 seconds. The engine must be started within that time or

the fuel solenoid will degenerize, and the switch must be tog-

gled to reset the timer.

Has two positions as follows:

1) In the “HIGH IDLE” position , the engine runs at the

high idle speed controlled by the governor.

2) In the “AUTO IDLE” / position, the idler

operates as follows:

• When switched from “High” to “Auto” or after starting the

engine, the engine will operate at full speed for approxi-

mately 12 seconds and then go to low idle speed.

• When the electrode touches the work or power is drawn

for lights or tools (approximately 100 watts minimum) the

engine accelerates and operates at full speed.

• When welding ceases and the auxiliary power load is

starts.

• If the welding or auxiliary power load is not restarted

before the end of the time delay, the idler reduces the

engine speed to low idle speed.

• The engine will automatically return to high idle speed

when the welding load or auxiliary power load is reap-

plied.

Idler Operational Exceptions -

When the WELDING

TERMINALS switch is in the REMOTELY CONTROLLED position

or the MODE SELECTION switch is in the ArcLink

®

position the

idler will operate as follows:

• When the triggering device (amptrol, arc start switch, etc.)

is pressed, the engine will accelerate and operate at full

speed, provided a welding load is applied within approxi-

mately 12 seconds.

• If the triggering device remains pressed but no welding

load is applied within approximately 12 seconds, the

engine may return to low idle speed.

• If the triggering device is released or welding ceases, the

engine will return to low idle speed after approximately 12

seconds.

AIR VANTAGE

®

600X-I