E-5

TROUBLE SHOOTING

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility

for technical troubleshooting assistance before you proceed.

ASPECT™ 375

Observe all Safety Guidelines detailed throughout this manual

CAUTION

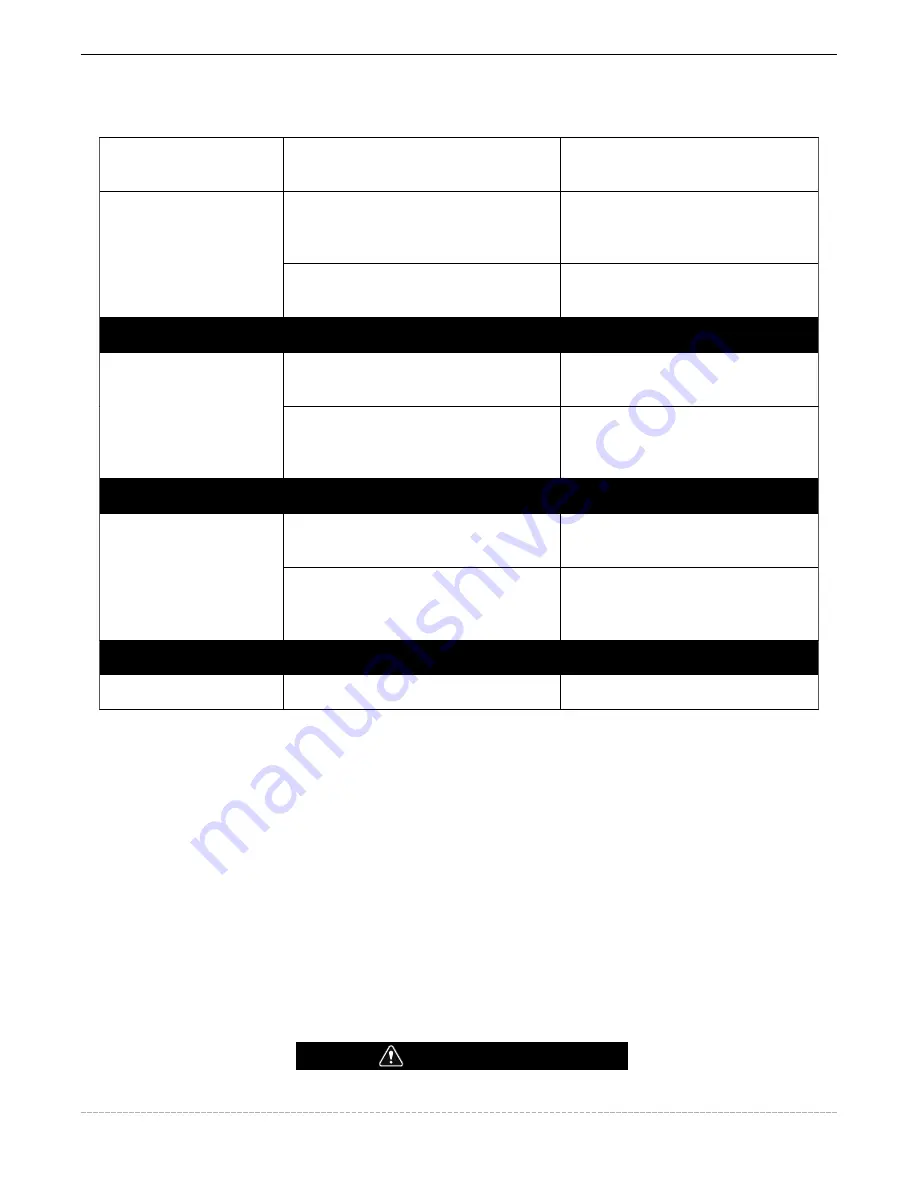

STICK WELDING ISSUES

SYMPTOMS

POSSIBLE CAUSE

Poor starting

Hot start may be set too low

Access “SMAW”menu (see

operation section) and increase

“HSTR” setting

Poor work clamp connection

Check and secure work

connection

Stick electrode “blasts

off” when arc is struck

Current may be set too high for

electrode size

Adjust current

Hot start set too high

Access “SMAW”menu (see

operation section) and reduce

“HSTR” setting

Electrode “sticks” in

weld puddle

Current may be set too low for

electrode size

Adjust current

Arc force set too low

Access “SMAW” menu (see

operation section) and increase

“FRCE” setting

Insufficient penetration

Wrong Process setting

Set Process for Crisp Stick

RECOMMENDED COURSE OF ACTION