E-10

TROUBLE SHOOTING

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility

for technical troubleshooting assistance before you proceed.

CAUTION

ASPECT™ 375

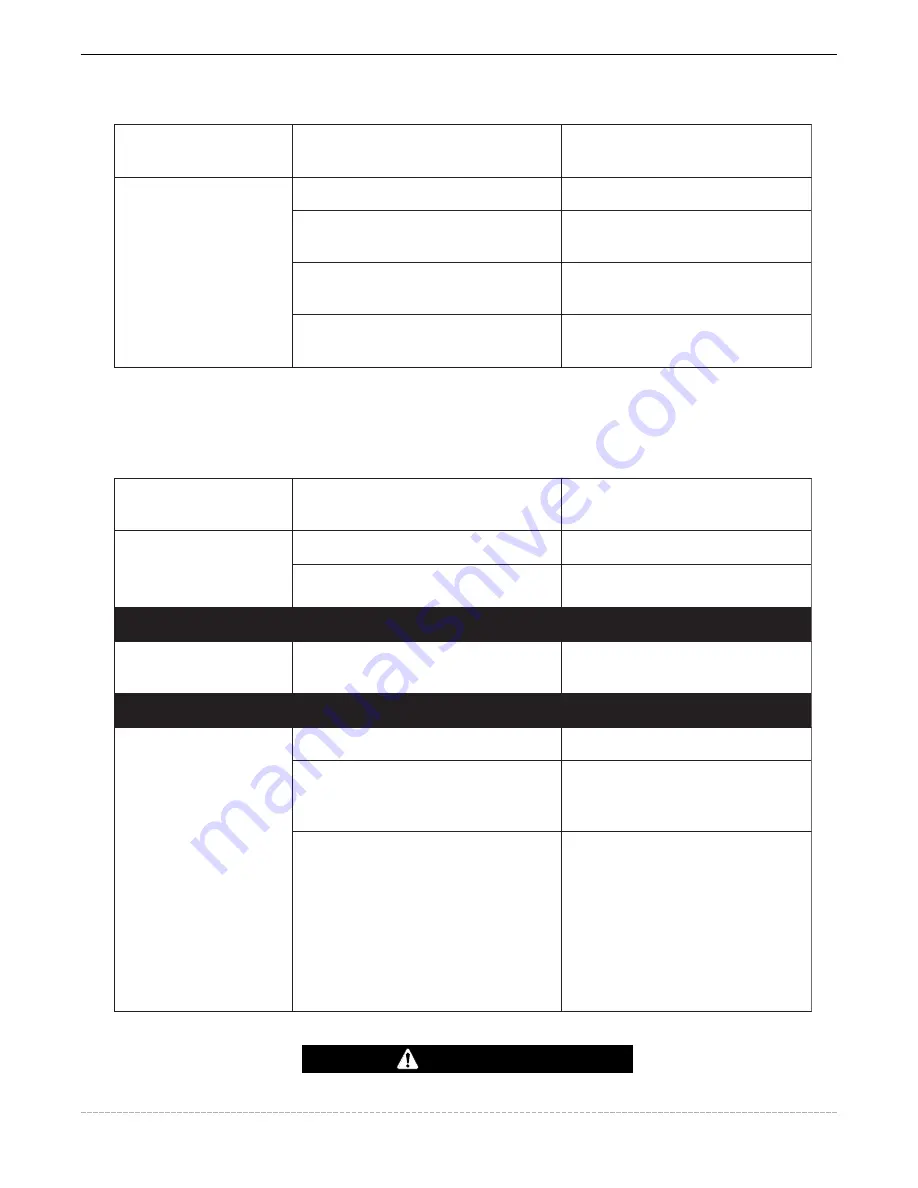

115V AUXILIARY OUTPUT ISSUES

SYMPTOMS

POSSIBLE CAUSE

RECOMMENDED COURSE OF ACTION

No output

Overload trips 115V circuit breaker

Remove load & reset breaker

Overload trips internal thermostat

Remove load & wait for thermostat

to reset

Faulty receptacle or connection

Check receptacle and

connection

Faulty PC Boards or connections

Contact your local Lincoln

Authorized Field Service Facility

WATER COOLER ISSUES

NOTE:

If cooler control cable is connected to or disconnected from machine when machine is already turned on,

machine must be recycled by turning off and then on so that cooler is recognized by machine; failure to do this

may damage Tig torch when welding

SYMPTOMS

POSSIBLE CAUSE

RECOMMENDED COURSE OF ACTION

Cooler is not plugged in

Plug cooler to 115V receptacle

No 115V output

Refer to 115V auxiliary outputsection

Tig torch runs hot

Cooler control cable is not plugged in

Turn machine off, plug control

cable, then turn machine on

Machine displays

ERR 11 when welding

Insufficient water in cooler

Check and refill water

Air in water line

Activate trigger and depress

Flow Sensor Bypass switch to

prime cooler

Cooler is not plugged in to 115V

receptacle, insufficient coolant in cooler,

TIG Torch is undersized (amperage

capacity) for application, blown fuse, or

faulty flow sensor inside cooler.

Initial Correction Measures:

Check

Cooler Connections, Fill Cooler with

additional Low Conductivity Coolant

(KP4159-1), Replace with higher

amperage capacity TIG Torch. Replace

3A fuse. Depress Flow Sensor Off

button to remove error code.

Secondary Corrective Measures:

Service cooler

Indicator light on cooler

does not turn on