A-1

INSTALLATION

A-1

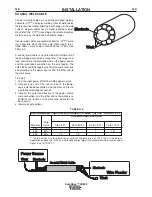

AutoDrive™ 4R220

TEMPERATURE RANGE

OPERATION:

-40°F to 104°F (-40°C to 40°C)

STORAGE:

-40°F to 185°F (-40°C to 85°C)

INPUT VOLTAGE, CURRENT

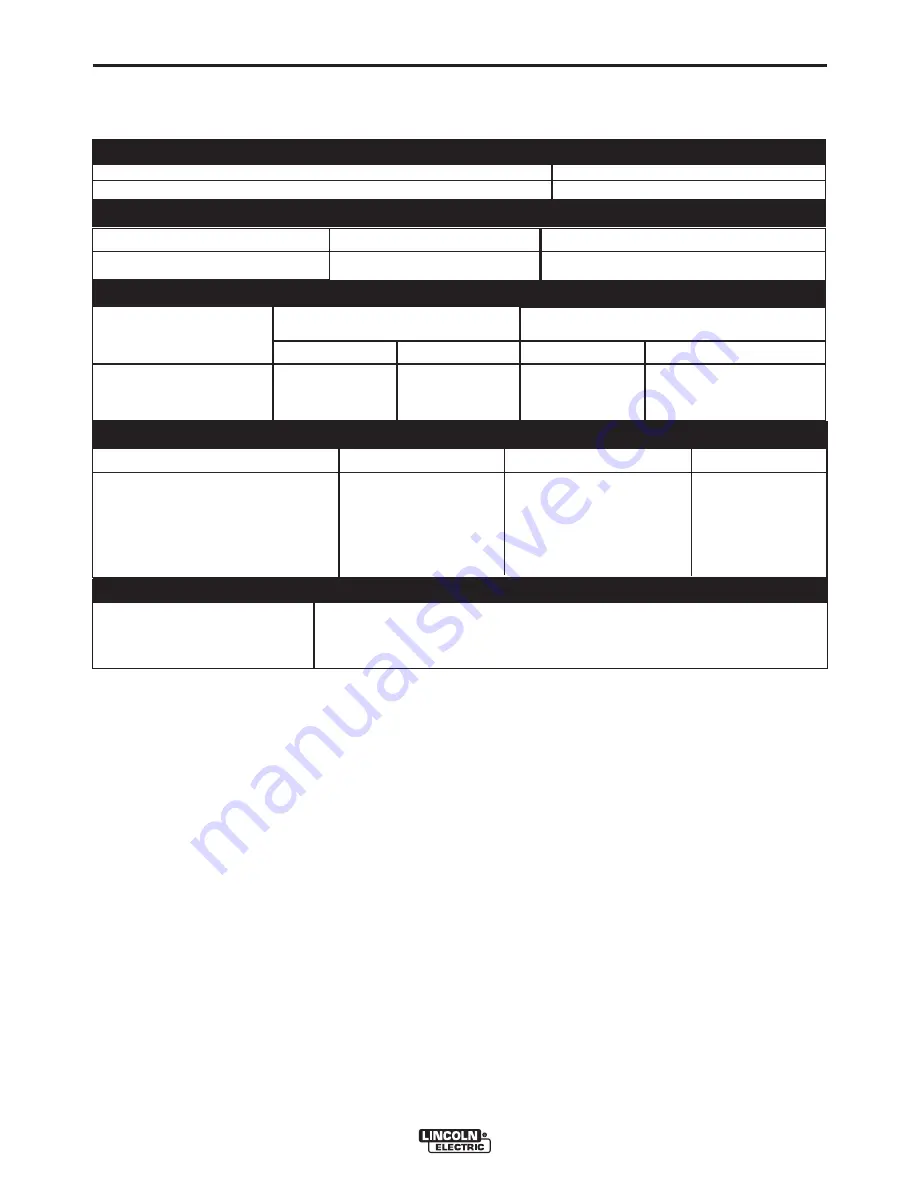

TECHNICAL SPECIFICATIONS – AutoDrive™ 4R220 (K2685-1)

HEIGHT

WIDTH

LENGTH WEIGHT

10.43 Inches

10.07 Inches 9.92 Inches

20.9 lbs.

(265 mm) (256 mm)

(252 mm) (9.5 kg.)

PHYSICAL DIMENSIONS

INPUT VOLTAGE ± 10%

40 VDC

INPUT AMPERES

7A

RATED OUTPUT @ 104°F (40°C)

DUTY CYCLE

100% rating

AMPERES

500

MOTOR POWER WATTS

220

GEARING - WIRE FEED SPEED RANGE-WIRE SIZE

WFS RANGE

50 – 1200 ipm

(0.8 – 30.5m/min)

WFS RANGE

50 – 1200 ipm

(1.3 – 30.5m/min)

WIRE SIZES

.023 – 1/16"

(0.6 – 1.6mm)

WIRE SIZES

.035 - 5/64”

(0.9 – 2.0mm)

GEARING

K2685-1

GMAW

FCAW

Summary of Contents for AUTODRIVE 4R220

Page 27: ...NOTES AutoDrive 4R220...