A-2

INSTALLATION

DEMO ZONE

A-2

SAFETY PRECAUTIONS

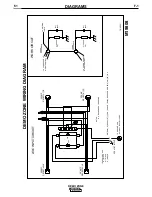

INPUT AND GROUNDING CONNECTIONS

INPUT POWER

The Demo Zone is designed to operate from 230 volt,

60 Hz single-phase input power with 40-amp capacity.

A 6-50R type receptacle must be provided by the

user. The receptacle must be installed by a qualified

person and must be in accordance with applicable

local and national electrical codes.

The lighting system requires 120 volt 60 Hz power.

Plug the line cord into a conventional 120 volt recepta-

cle for lighting operation. The lighting system is for

display and convenience purposes.

The Input Plugs for the Demo Zone are connected at the

factory.

GROUNDING

When the Demo Zone is connected to a conventional

power distribution system, the frame of the Demo

Zone must be grounded. The input cable provided

with the Demo Zone contains a grounding conductor.

Additionally, another ground lead must be connected.

Connect the frame of the Demo Zone to a good elec-

trical ground using the #1 AWG lead included with the

Demo Zone. The purpose of this additional ground is

to minimize disturbance of the high frequency unit and

to provide a path for stray welding currents.

Some applications may not use conventional input

power and instead utilize the generating capability of

the Ranger 250 for power. In this case, the ground

lead is required only if the high frequency unit of the

Square Wave TIG 175 is used.

OUTPUT CABLES AND

CONNECTIONS

ELECTRODE AND WORK CABLE CON-

NECTIONS

The Demo Zone is supplied with the output cables

connected at the power sources for positive electrode

polarity. To change the polarity of a power source,

switch the cables at the output terminals of the power

source, or change the power source polarity switch as

applicable.

A bolted work lead runs from the work buss connec-

tion of the Demo Zone to the work table. The work

table connection must be firm and secure.

ELECTRIC SHOCK can kill.

• Only qualified personnel should

perform this installation.

• Turn the input power OFF at the

circuit breaker or fuse box

before working on this

equipment.

• Do not touch electrically hot

parts.

• Always connect the Demo Zone to a power

supply grounded per the National Electrical

Code and any local codes.

• This demonstration rack is intended for

indoor use and display only.

• Shelter or protect from rain, moisture and

condensation.

• Do not operate electric equipment when

wet.

WARNING

CYLINDERS could explode

if damaged.

• Keep cylinders upr ight and

secured to a support.

• Keep cylinders away from areas

where they could be damaged.

• Never allow the electrodes or torches to touch

the cylinders.

• Keep cylinders away from live electrical circuits.

• Maximum inlet pressures must be observed.

CAUTION

------------------------------------------------------------------------

FALLING EQUIPMENT can cause

injury.

• Do not lift with gas cylinder in place.

• Do not trailer or transport over the

road

------------------------------------------------------------------------

ENGINE EXHAUST can kill.

• Use in open, well ventilated areas or

vent exhaust outside

------------------------------------------------------------------------

Summary of Contents for Demo Zone

Page 19: ...NOTES DEMO ZONE...