FineLine 300HD Plasma System

BK8053-000107 Rev A.01

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

Page 110 of 118

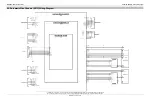

9.2 Cooling System (Inside Power Supply) Flow Diagram