FineLine 300HD Plasma System

BK8053-000107 Rev A.01

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

Page 30 of 118

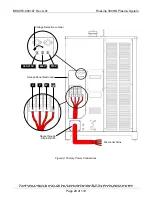

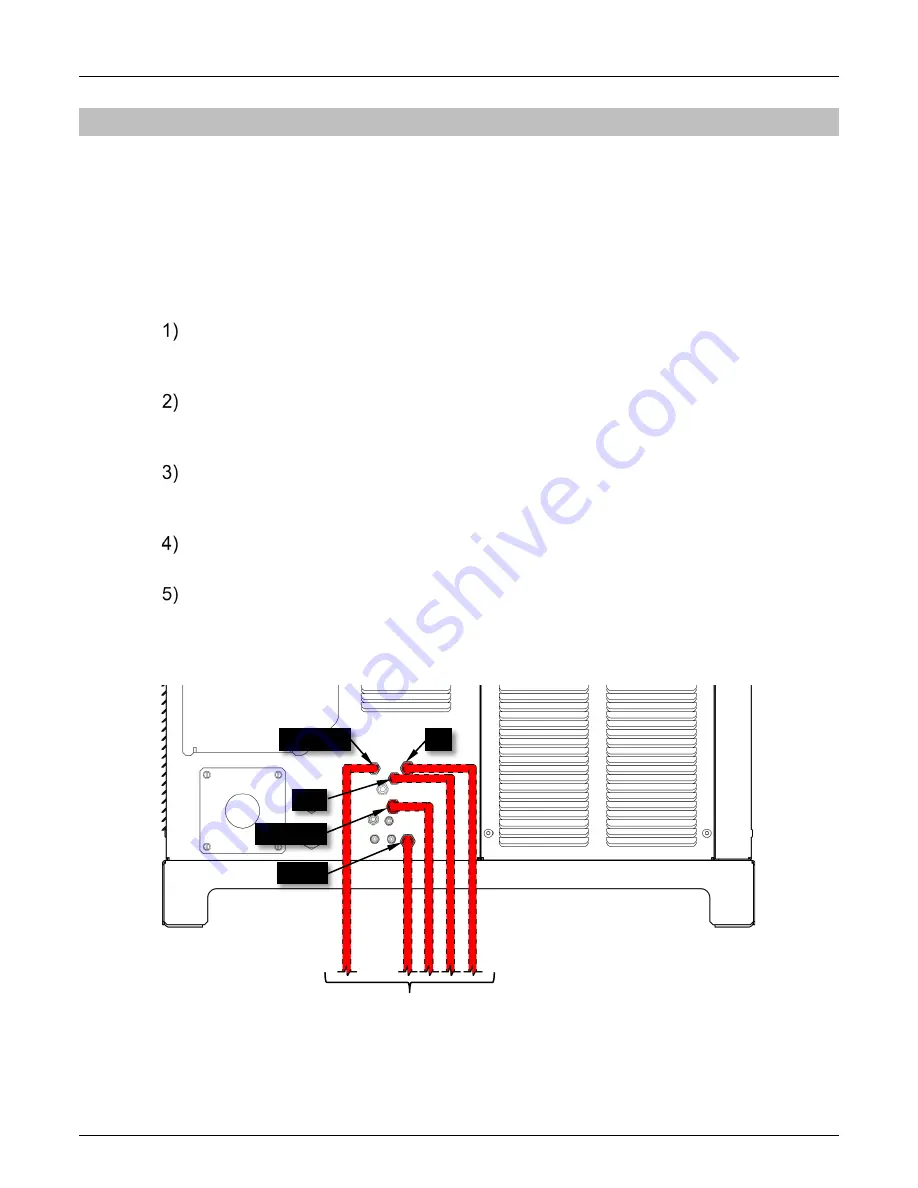

3.5 Power Supply Input Connections - Gas Supply

Connectors are sized for 3/8” inside diameter hose. Do not change the inlet gas

supply fittings to quick-connect fittings. Using quick-connect fittings to connect and

disconnect pressurized hoses may cause damage to the System. Gas supply hoses

can be supplied as an option. Refer to Figure 3 for the physical location of all

connections.

Make connections in the order shown below.

When making brass

fitting connections, use two opposing wrenches and only tighten enough to make

gas seals. The fittings are subject to damage if over tightened.

Argon Inlet

Argon is optional and provides improved marking capabilities. If not used, this

inlet should be capped.

Nitrogen Inlet

Nitrogen must be supplied for cutting stainless steel and aluminum; not required

for cutting mild steel.

H17 Inlet

H17 gas must be supplied to the unit when stainless steel is to be cut with H17

as the plasma gas. If not used, this inlet should be capped.

Air Inlet

Air must be supplied at all times, except when cutting stainless steel with H17.

Oxygen Inlet

Oxygen must be supplied to the unit at all times for cutting mild steel; not

required for cutting stainless steel or aluminum.

Figure 3: Gas Supply Connections

Nitrogen

Oxygen

Air

H17

Argon

From Gas Supply