E-3

TROUBLESHOOTING

E-3

CV-250

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility

for technical troubleshooting assistance before you proceed.

CAUTION

PROBLEMS

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENTS(S)

RECOMMENDED

COURSE OF ACTION

Machine has no output.

Machine has minimum output and no

control.

Machine has low output and no con-

trol.

1. Secondary contactor circuit (2

and 4 wire feeder receptacle) not

working.

2. Electrode or work lead loose or

broken.

3. Defective PC Board.

4. Protective circuits operating due

to output short circuit.

5. If using an LN-25, K484 jumper

plug kit not making connection

between 2 & 4 in wire feeder

receptacle.

6. If welding with 1/16" aluminum

wire and machine is flashing E00.

1. Voltage Control misconnected.

1. Open in feedback circuitry.

2. Faulty PC Board.

3. Voltage Adjust potentiometer

circuit open (lead 75).

1. Check 2 and 4 circuit wiring.

2. Repair connection.

3. See PC Board Troubleshooting

Procedure.

4. Turn power off. Remove output short

circuit.

5. Check for continuity between pins C

& D in the K484.

6. a) Turn power off to clear error. Use

recommended wfs, voltage set-

tings and angle of approach of

wire to work.

b) If problem still persists, call Local Lincoln

Authorized Field Service Facility.

1. Voltage Control wiring.

1. Check wiring and control and PC

board wiring harness plugs.

2. See PC Board Troubleshooting

Procedure.

3. Check and replace potentiometer if

faulty. Check wiring of lead #75.

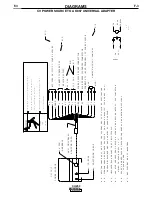

MACHINE TROUBLESHOOTING GUIDE

Not all trouble conditions can be recognized by the PC board, and displayed as error codes. The following guide

covers most other trouble conditions.