F-1

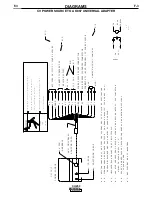

DIAGRAMS

F-1

CV-250

CONNECTOR CAVITY NUMBERING SEQUENCE

(COMPONENT SIDE OF P. C. BOARD)

ELECTRICAL SYMBOLS

PER E1537

+

-

L1

SECONDARY

THERMOSTAT

222

223

224

D4

C1

C2

C3

C4

+

+

+

+

R1

SCR2

D2

D5

222

204A

204D

CONTROL

P. C. BOARD

221

6 PIN

4 PIN

8 PIN

SNUBBER/BYPASS

P.C. BOARD

224

224A

224A

10A

CIRCUIT

BREAKER

CB1

L1 CHOKE

2

42V

12V

12V

-

204C

204D

204C

277

276

275

B

A

J

C

D

213

214

213

214

206

207

211

212

31

32

2

4

14 PIN

S2

M

L

N

G

F

E

H

VOLTMETER

CUSTOMER

CONNECTIONS

WIRE

FEEDER

115 VAC

42 VAC

GROUND

WIRE

FEEDER

RECEPTACLE

205

WIRE FEEDER

S3

3

1

SCR3

D3

SCR1

D1

8

2

3

4

1

7

6

5

213A

213A

OUTPUT

CONTROL

208

209

210

1

2

3

4

J7

METER

P.C.

BOARD

VOLTS / AMPS

1

5

9

3

2

4

2

5

3

4

1

6

6

1

5

4

7

3

8

G1

204A

G3

G2

3

1

2

4

J1

J3

J2

J4

21

N.A.

N.A.

J1

J4

J7

J2

J5

J3

J5

J5

223

221

G3

G2

G1

214A

1

2

218

219

400 A. 50mV

SHUNT

J10

2 PIN

J10

224B

224B

224B

213B

213B

213B

NC

(SHOWN IN "VOLTS" POSITION)

7.5 OHM

220 W

214B

214B

s

s

42A

42

41

42

I

K

C1-C4 31,000 MFD EACH

MAIN TRANSFORMER

C

2

41A

41

s

FAN

33A

31A

32

33

CIRCUIT

BREAKER

5A

CB2

115V

31B

31

31

10

8

12

11

202

200

203

201

s

s

58V

58V

O2 TOP

O1 TOP

O1 TOP

O3 TOP

O3 BOT.

VOLTMETER

SWITCH

76

77

75

277

276

S4

(SHOWN IN LOCAL POSITION)

LOCAL/REMOTE SWITCH

R2

10K

CW

376

77

377

N.A. WIRING VIEWED FROM REAR OF POTENTIOMETER

2

4

2

2

NC

+

-

2

L2

INPUT SUPPLY

LINES

S1

LINE

SWITCH

*

RECONNECT

PANEL

11

E

8

5

2

V

N.B.

B

UW

L1

L3

13

3

C

9

6

F

12

10

1

A

4

7

D

RECONNECT

PANEL

2

3 1

TO S1 LINE SWITCH

RECONNECT

PANEL

RECONNECT

PANEL

RECONNECT

PANEL

RECONNECT

PANEL

RECONNECT

PANEL

208/230/460 INPUT VOLTAGES

230/460/575 INPUT VOLTAGES

208V

230V

460V

230V

460V

575V

2

3 1

TO S1 LINE SWITCH

2

3 1

TO S1 LINE SWITCH

2

3 1

TO S1 LINE SWITCH

2

3 1

TO S1 LINE SWITCH

2

3 1

TO S1 LINE SWITCH

B

5

8

2

E

A

C

3

9

6

1

7

4

F

D

B

5

8

2

E

A

C

3

9

6

1

7

4

F

D

B

5

8

2

E

A

C

3

9

6

1

7

4

F

D

2

E

5

8

8

31

F

D

6

4

9

7

2

E

5

8

8

31

F

D

6

4

9

7

2

E

5

8

8

31

F

D

6

4

9

7

N.B. TAP LEADS A, B, AND C APPEAR ON THE TOP PRIMARY COILS

OF 208/230/460V MACHINES ONLY.

CLEVELAND, OHIO U.S.A.

3-10-95H

L9854

WIRING DIAGRAM CV 250 (60Hz)

TO A SYSTEM GROUND PER

NATIONAL ELECTRICAL CODE.

*

6

NC

7

NC

13

NC

14

NC

NC

NC

76

77

377

376

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The specific diag

ram for a particular code is pasted inside

the machine on one of the enclosure panels. If the diagram is illegible, write to the Service Department for a replacement. G

ive the equipment code number..