CAPACITOR DISCHARGE PROCEDURE

Service and repair should be performed by only Lincoln Electric factory trained personnel.

Unauthorized repairs performed on this equipment may result in danger to the technician or

machine operator and will invalidate your factory warranty. For your safety and to avoid elec-

trical shock, please observe all safety notes and precautions detailed throughout this manual.

If for any reason you do not understand the test procedures or are unable to perform the

test/repairs safely, contact the Lincoln Electric Service Department for electrical trou-

bleshooting assistance before you proceed. Call 1-800-833-9353 (WELD).

PURPOSE FOR THE PROCEDURE

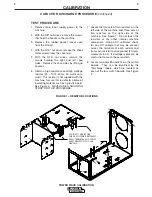

This procedure will drain off any charge stored in the four large capacitors that are part of the

FET switch board assembly. This procedure MUST be performed, as a safety precaution,

before conducting any test or repair procedure that requires you to touch internal compo-

nents of the machine.

MATERIALS NEEDED

Volt/Ohmmeter (Multimeter)

5/16" Nut driver

3/8" Nut driver

Insulated gloves

Jumper wire with insulated leads and needle-nose ends

High wattage resistor - 25 to 1000 ohms, 25 watts minimum

Piece of glastic board or similar insulating materials on which to secure the resistor

WARNING

CALIBRATION

4

4

POWER WAVE CALIBRATION