A-4

INSTALLATION

V155-S

A-4

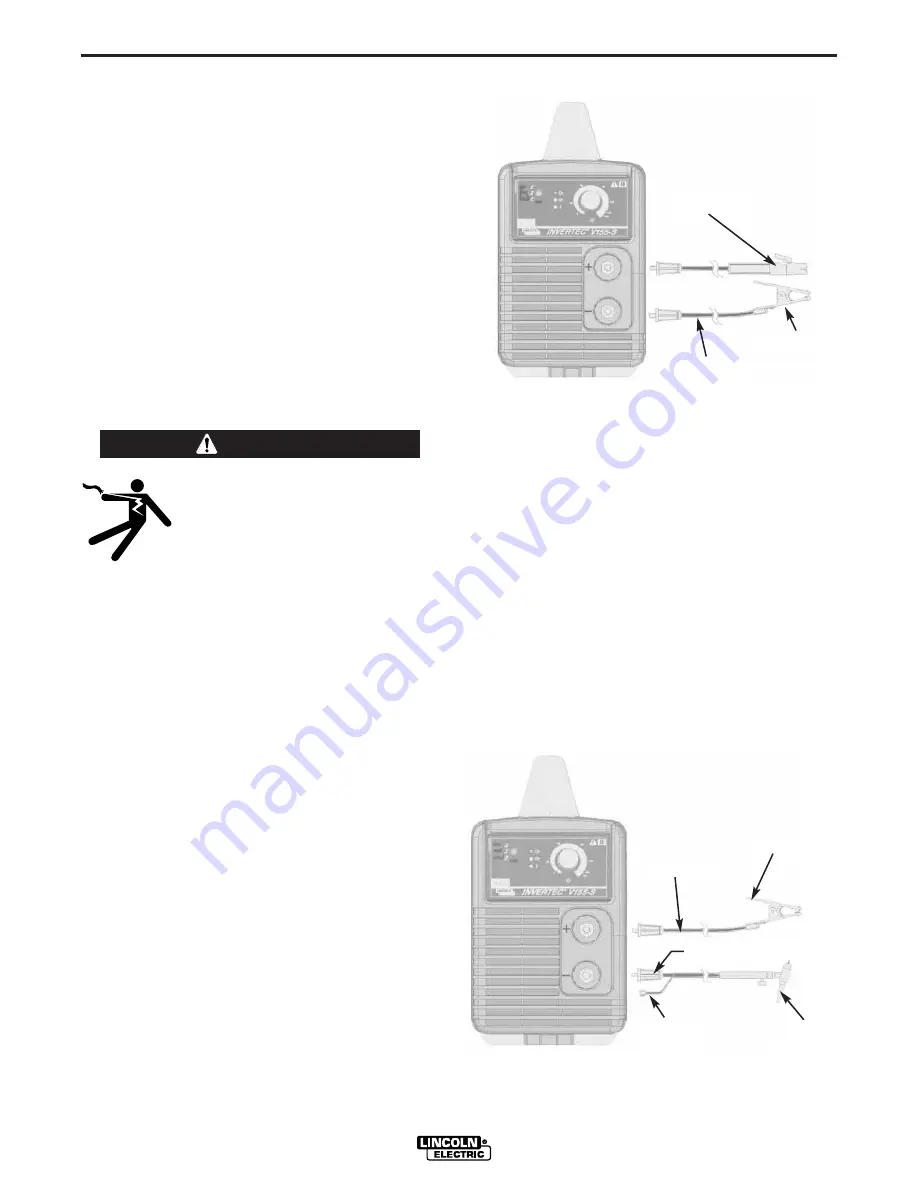

TIG WELDING

This machine does not have a built in Gas Solenoid

so a one piece gas valve TIG Torch is required. A

K960-2 Twist-mate TIG Torch adapter is also required.

Refer to the accessories section for more information

about TIG Torches and required Twist-mate adapter.

Most TIG welding is done with DC(-) polarity shown

here. If DC(+) polarity is necessary switch the cable

connections at the machine. (See Figure A.2)

Connect the torch cable to the (-) terminal of the

machine and the work clamp to the (+) terminal.

Insert the connector with the key lining up with the

keyway and rotate approximately 1/4 turn clockwise.

Do not over tighten. Finally, connect the Twist-mate

adapter gas hose to the gas regulator on the cylinder

of gas to be used.

FIGURE A.2

Work Clamp

Twist-mate Adapter K-960-2

Work Cable

Gas Valve

TIG Torch

Gas Hose

To Bottle

ARFU (Auto-Restore Fuse)

The dual input voltage machine is provided with the

ARFU device. It operates only when the input is con-

nected to the 120Vac mains and protects from input

overcurrent. When active, the "Thermal LED" lights

(see "Controls and Operational Features" in the

Operation Section).

Note: The ARFU device operates independently from

the machine's duty-cycle.

OUTPUT CONNECTIONS

A quick disconnect system using Twist-Mate™ cable

plugs is used for the welding cable connections.

Refer to the following sections for more information on

connecting the machine for operation of stick welding

(MMA) or TIG welding.

ELECTRIC SHOCK can kill.

• Keep the electrode holder and

cable insulation in good condition.

• Do not touch electrically live parts

or electrode with skin or wet cloth-

ing.

• Insulate yourself from work and ground.

• Turn the input line Switch on the Invertec V155-

S “off” before connecting or disconnecting out-

put cables or other equipment.

-----------------------------------------------------------

STICK WELDING (MMA)

First determine the proper electrode polarity for the elec-

trode to be used. Consult the electrode data for this

information. Then connect the output cables to the out-

put terminals of the machine for the selected polarity.

Shown here is the connection method for DC(+) welding.

(See Figure A.1)

Connect the electrode cable to the (+) terminal and the

work clamp to the (-) terminal. Insert the connector with

the key lining up with the keyway and rotate approxi-

mately 1/4 turn clockwise. Do not over tighten.

For DC(-) welding, switch the cable connections at the

machine so that the electrode cable is connected to (-)

and the work clamp is connected to (+).

Work Clamp

Work Cable

Electrode

Holder

FIGURE A.1

WARNING

Summary of Contents for INVERTEC V155-S 11326

Page 6: ...v SAFETY v EN 60974 10...

Page 7: ...vi SAFETY vi EN 60974 10...