D-1

MAINTENANCE

ELECTRIC SHOCK CAN KILL.

•

Turn the input power OFF at the

welding power source before

installation or changing drive rolls

and/or guides.

•

Do not touch electrically live parts.

•

When inching with the gun trigger, electrode and drive

mechanism are "hot" to work and ground and could

remain energized several seconds after the gun trigger

is released.

MOVING PARTS can injure.

•

Do not operate with covers, panels or

guards removed or open.

•

Only qualified personnel should perform

maintenance work.

Disposal

After life of the product, dispose of product in accordance with

federal, state or local regulations.

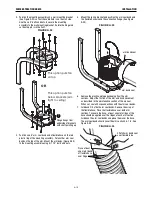

When cleaning equipment or replacing filter

use personal protection equipment (PPE)

such as gloves, respirators and protective

clothing to protect against overexposure to

particulate. It is recommended that a

vacuum cleaner or wet methods be used to

clean up any loose particulate that is present in the

extraction arm. It is necessary to use a vacuum cleaner with

HEPA rated filtration.

service, Maintenance anD repairs

• Observe the maintenance intervals given in this manual.

Overdue maintenance can lead to high costs for repair and

can render the guarantee null and void.

• During service, maintenance and repair jobs, always use

Personal Protective Equipment (PPE) to avoid injury. This also

applies for persons who enter the work area.

• Always use tools, materials, lubricants and service techniques

which have been approved by the manufacturer. Never use

worn tools and do not leave any tools in or on the product.

• Safety features which have been removed for service,

maintenance or repairs, must be put back immediately after

finishing these jobs and it must be checked that they will still

function properly.

• Use sufficient climbing gear and safety guards when working

higher than 2 meters (local restrictions may apply).

• Ensure the workspace is well illuminated.

The product has been designed to function without problems for a

long time with a minimum amount of maintenance. In order to

guarantee this, some simple regular maintenance and cleaning

activities are required which are described in this chapter. If you

observe the necessary caution and carry out the maintenance at

regular intervals, any problems occurring will be detected and

corrected before they lead to a total breakdown. The indicated

maintenance intervals can vary depending on the specific working

and ambient conditions. Therefore it is recommended to

thoroughly inspect the complete product once every year beside

the indicated periodic maintenance. For this purpose contact your

supplier. See Table D.1.

Risk of Fire

PAST due maintenance can cause fire.

WARNING

WARNING

WARNING

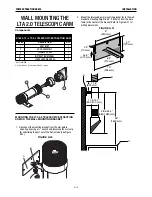

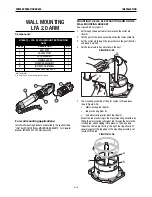

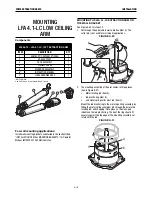

FUME EXTRACTION ARMS

MAINTENANCE

Summary of Contents for K1655-10-LTA 2.0

Page 43: ...ii THIS PAGE INTENTIONALLY LEFT BLANK...

Page 61: ...P 968 C jpg LFA 4 1 K2633 7 General Assembly LFA 4 1 K2633 7 14 13...

Page 63: ...P 969 C jpg LFA 4 1 K2633 8 General Assembly LFA 4 1 K2633 8 14 13...

Page 64: ...ii THIS PAGE INTENTIONALLY LEFT BLANK...