39

User Guide

As Needed Maintenance (Cont.):

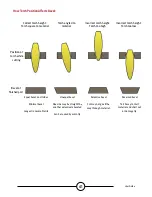

Slats:

Over time the slats will accumulate build up that will create an uneven cutting surface and poor continuity to the

table that will directly affect your cut quality. When this occurs, replace the slats with new slats.

The slat size used in the 4x00 tables are 3/16” (T), 2” (H), 53” (L) for the 4400/4800 tables. The slats will be 61" (L) for

the 4510 table. If the machine is used to cut primarily in the front of the table, another option is to rotate the slats

from back to front and vice versa.

Clean the slats off by using a pneumatic needler or grinder and then flip the slats over to elongate use.

Water Pan:

The water in the pan needs to be drained and cleaned every 2-4 months based on usage. There is a plumbing valve

(1/2 inch) located in the back left corner of the table.

To dispose of water, please contact your local EPA or water district authorities. After the water has been drained,

remove all pieces of metal and discard according to local and federal regulation.

Close the valve and refill the table with water. The 4400 holds 60 gallons (230 liters), the 4800 holds 107 gallons (405

liters), and the 4510 holds 140 gallons (530 liters).

Lincoln Electric Cutting Systems recommends PLATEGUARD

©

(TMS-310-0001-00) as a water additive for rust

prevention and anti-bacterial growth. Add the recommended quantity per machine.

Visit

for more information and to purchase.

Please Note:

•

The purchasers of products from Lincoln Electric Cutting Systems are responsible for disposing of consumables, fluids,

and machinery at the end of the life cycle in accordance with federal and local regulations.