45

Installation and Operations Guide

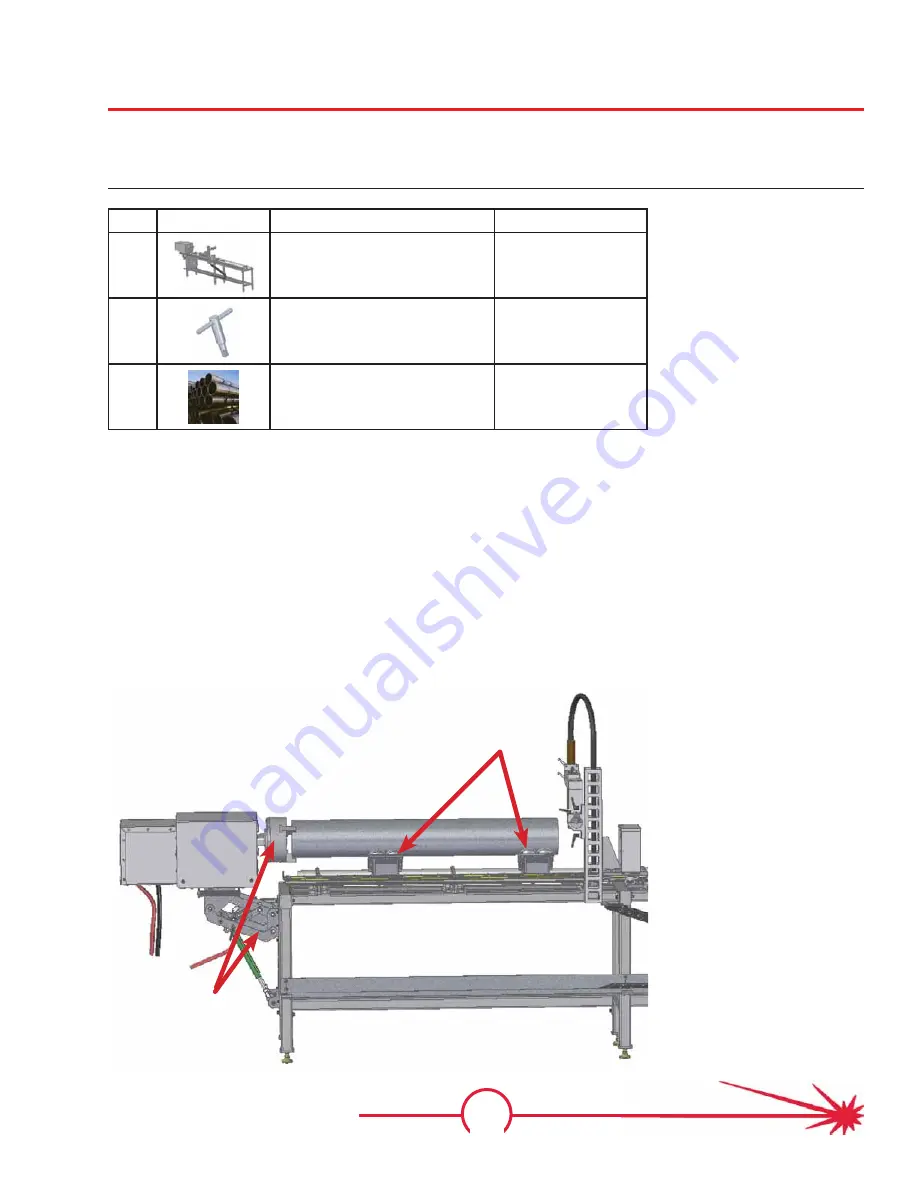

Step 26: Load material for speed and demo cuts

Your MASTERPIPE Mini Profile can manage material from 1” to 8” in production work, so

changing pipe diameter is important. For or speed and demo cuts, you will load a length of 6”

I.D. Schedule 40 pipe (4’ long or greater) and set the MPMP chuck height to grip it.

Qty

Part

Description

Part #

1

MPMP with CNC Controller

and computer

From Step 25

1

Chuck key

Included with base

machine chuck

1

4’ or greater length of 6” I.D.

Sch. 40 pipe

(from your stock or

scrap)

Required parts /

components

Instructions

• Obtain a 4’ or longer length of Sch. 40 pipe with an I.D. of 6” and

load it onto the ball transfer cradles.

• Loosen the height adjustment levers and set the chuck height and

jaw opening to hold the pipe.

• Lightly tighten the jaws with the chuck key.

• Jog the chuck (X-axis) in either direction. Refer to Step 24.

Tighten the jaws with a medium tightness, and lock the height.

• There is no need to over tighten the chuck jaws.

• Set the pipe diameter to 6.625 as in Step 25.

Illustration

Load the 6” ID Sch

40 pipe onto the

ball cradles

Adjust the

chuck height,

then tighten

chuck jaws with

the chuck key

Summary of Contents for MASTERPIPE Mini Profiler

Page 9: ...1 Safety Guide Safety Information ...

Page 19: ...11 Installation and Operations Guide Hardware Installation ...

Page 62: ...54 MASTERPIPE Mini Profiler ...

Page 63: ...55 Driver Software Driver Introduction ...

Page 65: ...57 Driver Software Illustrations screen shots of the TM4 installation pro cess ...

Page 67: ...59 Driver Software Illustrations screen shots of the device driver installa tion process ...

Page 96: ...88 MASTERPIPE Mini Profiler ...

Page 97: ...89 Installation and Operations Guide Parts ...

Page 100: ...92 MASTERPIPE Mini Profiler ...

Page 101: ...93 Installation and Operations Guide Troubleshooting ...