49

Installation and Operations Guide

Step 30: Cut the speed test

With the pipe loaded on the machine, the speed test cut file loaded on the computer, the cor-

rect consumables for the selected amperage, and the plasma cutter’s compressed gas supply

available and its configuration set according to the cut charts, you are ready to cut the speed

test.

Qty

Part

Description

Part #

1

MPMP system

From Step 29

Required parts /

components

Instructions

• Check on the following pre-cut conditions:

• Cut file is loaded and TM4 shows “Connected” status.

• Air / gas supply is connected and in the correct pressure range.

• Air is being directed through the chuck.

• Correct amperage range has been selected for the installed

consumables.

• The torch height is correctly set.

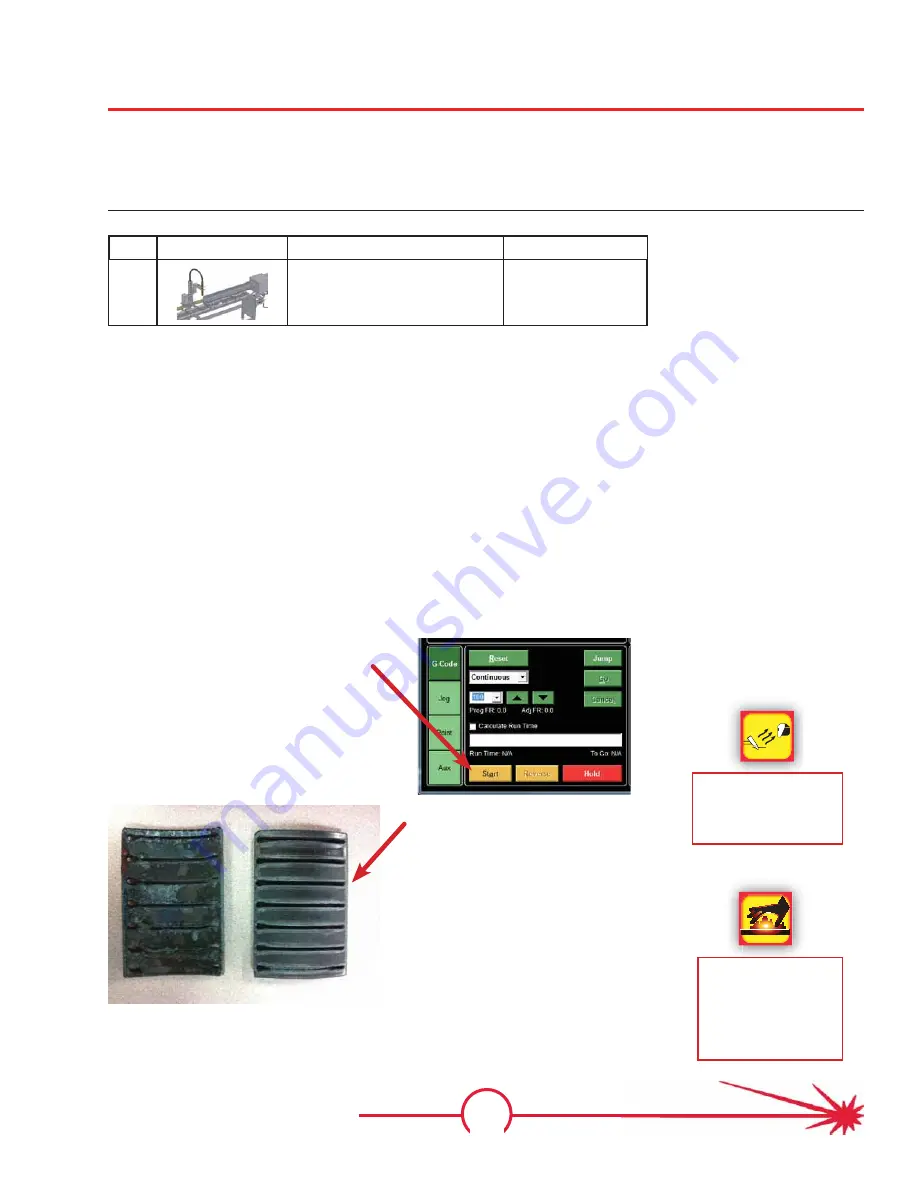

• Click on the

Start

button to begin cutting.

Illustration

Click the

Start

button

WARNING

Cut parts retain heat

for many minutes.

Handle only with

approved tools until

fully cooled.

Lower speeds

Higher speeds

Select the cut with the least combi-

nation of bevel and dross. From the

file’s speed range, note the speed.

Wear eye protection

while watching the

plasma arc. Review

the safety chapter.

Summary of Contents for MASTERPIPE Mini Profiler

Page 9: ...1 Safety Guide Safety Information ...

Page 19: ...11 Installation and Operations Guide Hardware Installation ...

Page 62: ...54 MASTERPIPE Mini Profiler ...

Page 63: ...55 Driver Software Driver Introduction ...

Page 65: ...57 Driver Software Illustrations screen shots of the TM4 installation pro cess ...

Page 67: ...59 Driver Software Illustrations screen shots of the device driver installa tion process ...

Page 96: ...88 MASTERPIPE Mini Profiler ...

Page 97: ...89 Installation and Operations Guide Parts ...

Page 100: ...92 MASTERPIPE Mini Profiler ...

Page 101: ...93 Installation and Operations Guide Troubleshooting ...