8695 9007 / F

MEC 4

E-21

E - MAINTENANCE

Before any work, stop the welding equipment

1 - SERVICING

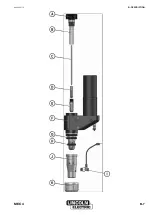

The

MEC4

welding torch is the location of different phenomena that create the

electric arc. For that, it is supplied with:

electrical energy

annular gas

cooling water

through a bundle of pipes and cables.

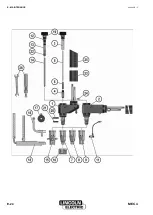

COMMENTS:

Assembly errors or the omission of parts would harm the life of the torch.

While removing or assembling the parts making up the torch, handle the parts

with care to avoid breaking, scratching or marking them.

Always use original LINCOLN ELECTRIC parts.

BUNDLE:

The bundle must be installed so that it is safe from mechanical, chemical and

thermal damage.

Monitor the condition of the sleeve covering the bundle.

If it is defective, explore the condition of the various conduits that make up the

bundle.

Also check the cable to the piece (ground cable)

Work for maintaining and repairing insulating sleeves, pipes and enclosures

may not be carried out in a haphazard manner.

Regularly check all the connections and make sure that the electrical

connections are not heating.

REGULARLY CHECK:

O-ring seals; if these are damaged, replace them, taking care not to scratch

their housing.

REGULARLY CLEAN:

the accessible parts of the torch body with a dry cloth. Any water drips must

be dried before reassembly.

NB: The alumina cap must be screwed in and tightened by hand.

Every time the cap is fitted, clean the thread of the torch body.