E-2

TROUBLESHOOTING

E-2

MINIFLEX

Observe all Safety Guidelines detailed throughout this manual

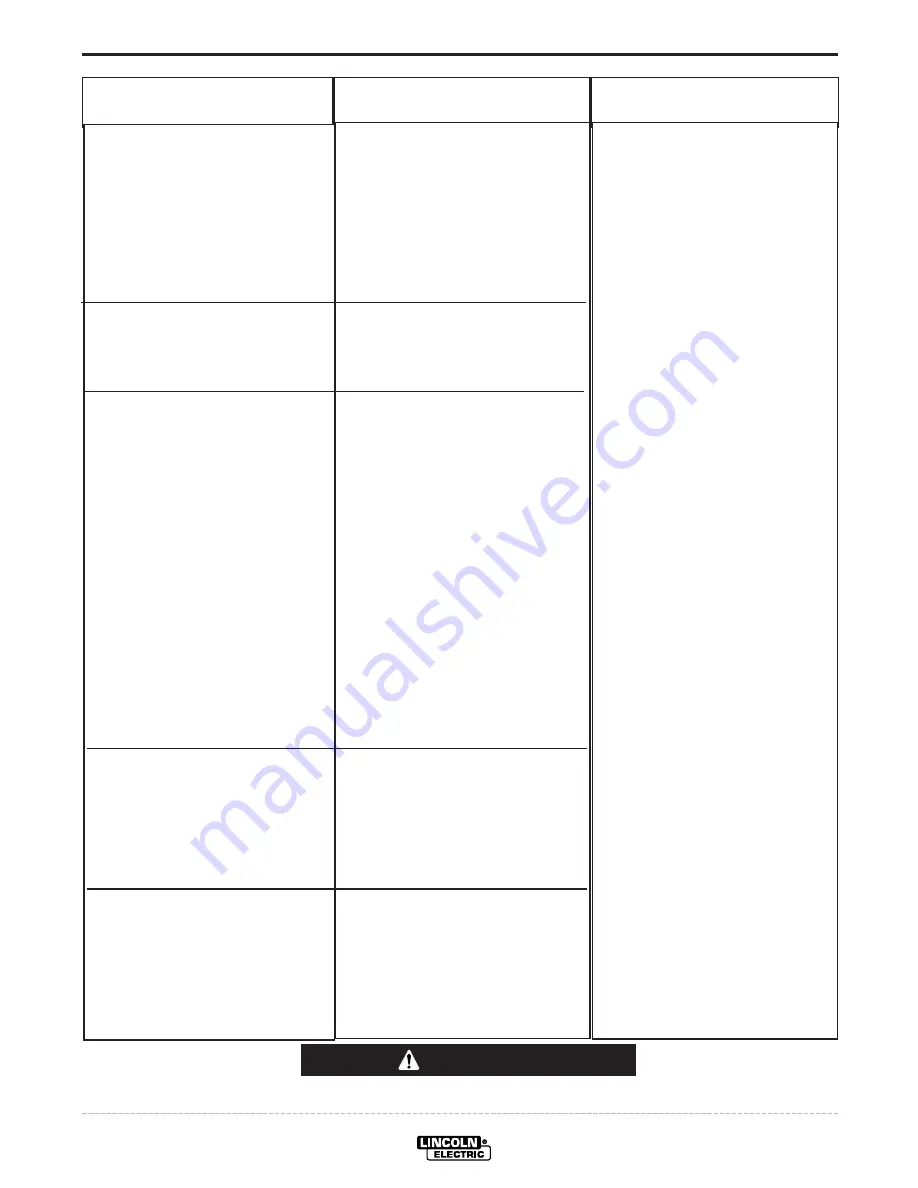

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Motor does not start.

Motor stops automatically.

Poor suction.

Unit will not sense current.

Unit automatically cycles between

low and high speeds.

1. Ensure 115 VAC input power is

available.

2. Circuit breaker tripped. Reset cir-

cuit breaker (See Electrical

Maintenance)

.

3. Carbon brushes worn. Check

brushes, replace if necessary.

1. Thermal protection is activated.

Check that the cooling underneath

the top cover and/or the outlet are

not obstructed.

1. Leakage. Check hose connections,

hose integrity.

2. Filter dirty. Replace both LongLife-

H™ Filter and HEPA filter.

3. Pre-filter dirty. Check pre-filter and

replace or clean using an industrial

vacuum cleaner. Use caution and

proper personal protection equip-

ment when cleaning pre-filter.

4. Improper application. Check hose

diameter and maximum length 24

ft. (7.5 m), check filter for oily con-

ditions.

5. Brushes worn in one of the motors.

Replace brushes in both motors.

1. Welding current too low. Loop

cable two or three times on current

sensor.

2. Current sensor or PC board dam-

aged. Replace sensor or PC

board.

1. Check connections from PC board

to motors.

2. Control panel/PC board damaged.

Replace control panel and PC

board.

If all recommended possible areas

of misadjustment have been

checked and the problem persists,

Contact your local Lincoln

Authorized Field Service

Facility.

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility

for technical troubleshooting assistance before you proceed.

CAUTION