Miniflex

™

[2]

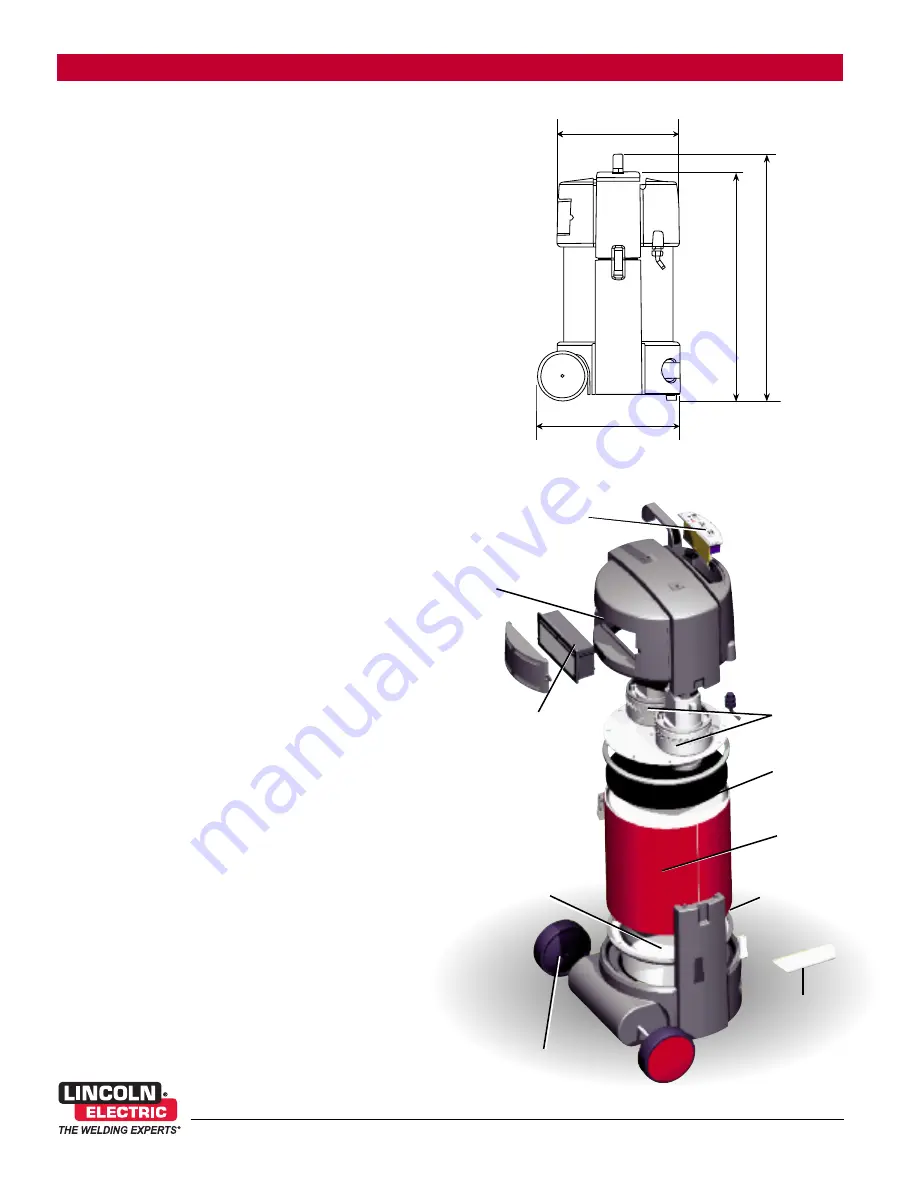

A CLOSER LOOK

Ø 360 mm

420 mm

6

7

5

m

m

7

3

0

m

m

Weight and Design

Constructed out of synthetic components, the Miniflex is light-

weight, at only 36 lbs. (16 kg), and impact resistant with a user-

friendly design. With wheels and handle standard, the Miniflex can

be easily rolled or carried around, unlike competitive models.

Five-Stage Filtration Process

The Miniflex has a five-stage filtration process. In stage one, as the

air enters the system through an intake connection, it passes

through a removable and washable metal pre-filter in which heavier

particles and foreign material are captured. In stage two, the air

passes through a second metal pre-separator to further reduce any

large particle matter from reaching the LongLife-H main filter. In

stage three, the air passes through the LongLife-H main filter where

the welding fume particles are captured and deposited. In an

optional stage four, after flowing through the LongLife-H filter, the

air passes through the optional activated carbon filter to help

prevent or neutralize the release of odors back into the

environment. In the final stage (stage five), the air passes through a

HEPA filter (also known as High Efficiency Particle Air).

LongLife-H filter

The unique design of the Miniflex's LongLife-H main filter has

resulted in a very large filter surface area equaling 130 ft2 (12 m2).

With such a large surface area, the filter has an extended life. The

LongLife-H filter is designed to dispose of extracted welding fume

deposits at the time of filter disposal, preventing deposits from

being released during welding.

Cable Sensor

At the top of the Miniflex unit is an automatic start/stop button and

a manual button. When the Miniflex is being operated in automatic

mode, the unit automatically switches on as welder begins to weld,

and automatically switches off approximately 15 seconds after

welder stops welding. The result is less energy consumption and

non-continuous noise. For the automatic start/stop function to

work, the welder’s work cable or power cable must be laid across

the top of the Miniflex unit in the slotted groove with an integrated

sensor.

When the Miniflex is being operated in manual mode, the unit is

continuously running.

Reduced Noise

Smart noise insulation around the air exhaust significantly reduces

noise without overheating the motors. 70dB(A) with nozzle

extraction installed.

Two Parallel Motors

The Miniflex is powered by two 1.2 hp motors allowing for sufficient

extraction capacity under all conditions. At the top of the Miniflex

unit is a high/low button. In high mode, both motors are working at

100% capacity, extracting 135 CFM of air. In low mode, both

motors are working at 50% capacity, extracting 94 CFM of air. With

both motors increasing and decreasing speed, the result is a

continuously balanced system with reduced maintenance. The

motors parallel positioning design reduces noise.

Automatic Start/Stop for

less energy consumption,

convenience and longer

filter life.

Wheels standard

for easy portability.

Stage 5

HEPA Filter

(KP2390-2)

for higher

filtration

efficiency.

Two motors

for better

performance.

Stage 3

LongLife-H Filter

(KP2390-1)

Intake Connection for

Extraction Hose.

www.lincolnelectric.com

14-1/4 in.

2

6

-1

/2

in

.

2

8

-3

/4

in

.

16-1/2 in.

Stage 4

Activated

carbon filter.

(K2389-1 Optional)

Stage 1

Pre-filter captures larger

particles and drops

particulate matter into

collection tray.

Smart noise

insulator.

Stage 2

Pre-separator for

capturing medium

to heavy particulate

matter.