F-61

TROUBLESHOOTING & REPAIR

F-61

TEST PROCEDURE

Perform the following checks with the

NA-5 connected to a Lincoln CV weld-

ing power source according to the prop-

er connection diagram. See the

Installation Section of this manual.

1. Check to make sure the speedmeter

calibration jumper is connected to

the proper calibration pin for the

head and drive roll system being

used. See Table F.3

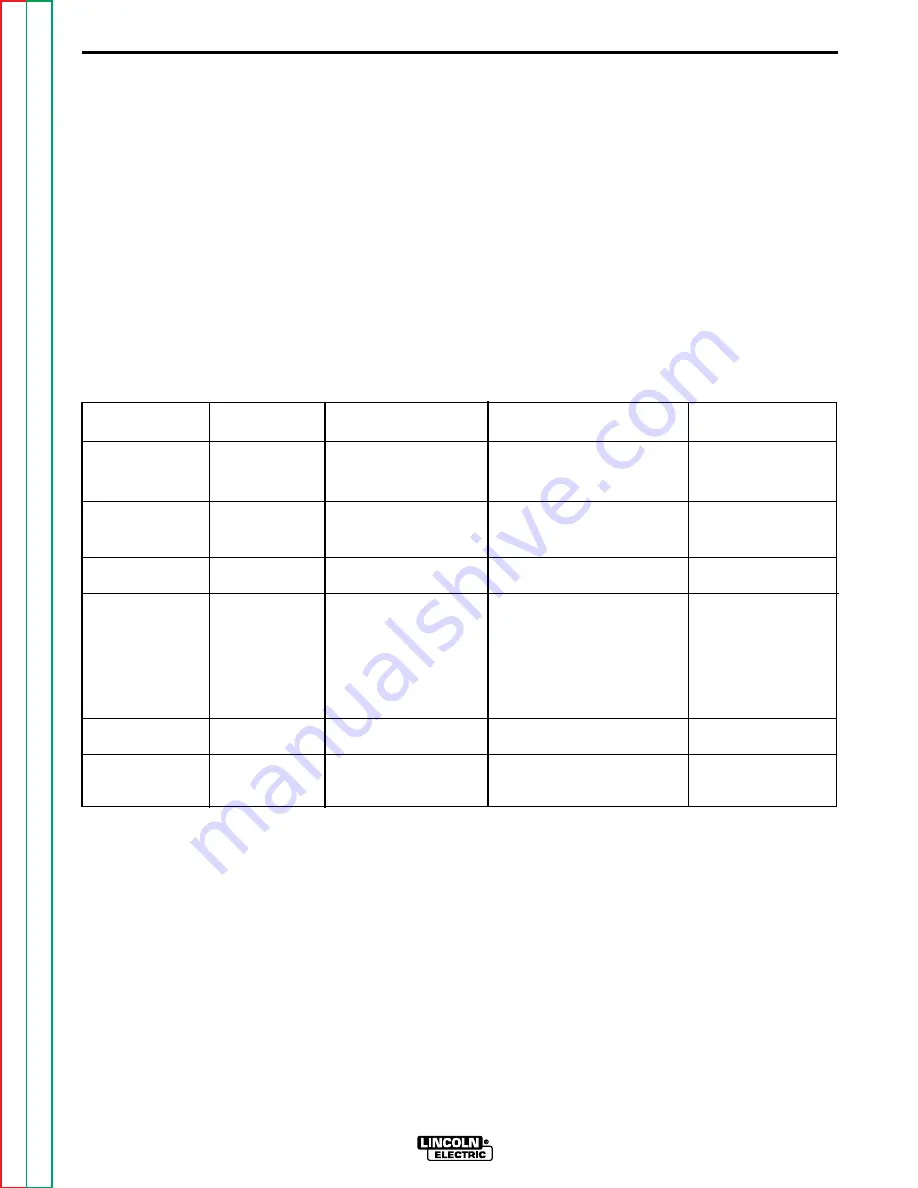

WIRE SPEED ACCURACY TEST

(Continued)

NA-5

SPEEDMETER

HEAD

DRIVE ROLL

WIRE SIZE RANGE

RATED SPEED

CALIBRATION

RATIO

PART NUMBER

RANGE (IPM)

21*

21/1

S12778

Single .035 - .052 Solid

100 - 2070

S19113

Single .045 - .052 Cored

57F**

57/1

S12778

Single .035 - .052

40 - 778

57**

57/1

S12515

Single 1/16 - 3/32

38 - 762

95

95/1

S12514

Single 3/32 - 5/32

22 - 428

95S***

95/1

S12515

Single 1/16 - 3/32

23 - 456

S19113

Single .045 - .052 Cored

S13161-052

Twin .045 -.052

S13161-5/64

Twin 1/16 - 5/64

S14904 (Outer)

Twin 3/32

S14905 (Inner)

142

142/1

S12514

Single 3/32 - 7/32

15 - 289

142T***

142/1

S14904 (Outer)

Twin 5/64 - 1/8

15 - 300

S14905 (Inner)

TABLE F.3

* Present on HI -Speed NA-5 speedmeter board only. ** Early speedmeter pins were labeled 55F and 55,

respectively.

*** Early speedmeter PC boards did not include these calibration pins.

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC