English

English

36

Welding GMAW-P Process in synergic mode

Table 19. Exemplify GMAW-P programs

Wire material

Gas

Wire diameter

0.8

0.9

1.0

1.2

1.4

1.6

Steel

ArMIX

95

140

12

22

26

108

Steel (RapidArc

®

)

ArMIX

-

141

13

18

27

106

Steel (Precision Pulse™)

ArMIX

410

411

412

413

-

-

Stainless

ArMIX

66

30

36

46

-

-

Stainless

Ar/He/CO

2

64

-

34

44

-

-

Metal Core

ArMIX

-

-

-

82

84

-

Ni Alloy

70%Ar/30%He

-

-

170

175

-

-

Si Bronze

Ar

-

-

192

-

-

-

Copper

ArHe

-

-

198

196

-

-

Aluminum AlSi

Ar

-

-

-

72

-

74

Aluminum AlMg

Ar

-

-

152

76

-

78

Note:

The list of available programs depends on the power source.

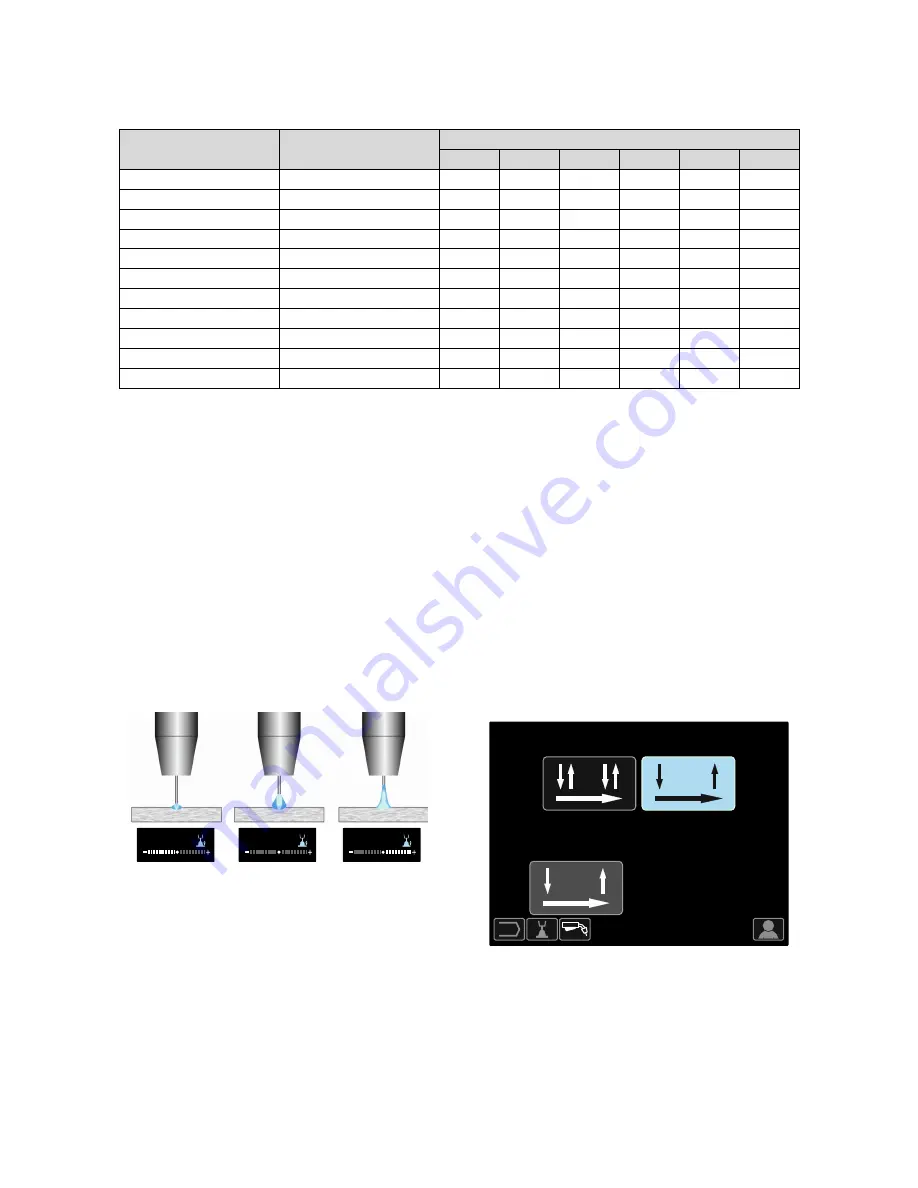

Synergic GMAW-P (Pulsed MIG) welding is ideal for low

spatter, out of position. During pulse welding, the

welding current continuously switches from a low level to

a high level and then back again. Each pulse sends a

small droplet of molten metal from the wire to the weld

puddle.

Wire Feed Speed [9] is the main control parameter. As

the Wire Feed Speed is adjusted, the power source

adjusts the waveform parameters to maintain good

welding characteristics.

Trim [10] is used as a secondary control – the value of

parameter in the upper right side of display [26]. The

Trim setting adjusts the arc length. Trim is adjustable

from 0.50 to 1.50. 1.00 is the nominal setting.

Increasing the Trim value increases the arc length.

Decreasing the Trim value decreases the arc length.

1.00

0.50

1.50

Figure 75

When Trim is adjusted, the power source automatically

recalculates the voltage, current and time of each part of

the pulse waveform for the best result.

Additionally can manually set:

••••

Burnback

••••

Run-In WFS

••••

Preflow Time/ Postflow Time

••••

Spot Time

••••

2-Step/4-Step

••••

Crater

••••

Wave Control

••••

UltimArc™

The 2-Step - 4-Step

changes the function of the gun’s

trigger.

•

2 Step trigger operation turns welding on and off in

direct response to the trigger. Welding process is

performed when the gun’s trigger is pulled.

•

4-Step mode allows to continue welding, when the

gun’s trigger is released. To stop welding, the gun’s

trigger is pulled again. 4-step mode facilitates to

making long welds.

Note:

4-Step does not work during Spot Welding.

M

Figure 76