English

English

38

Aluminum Welding GMAW- PP Process in synergic mode

Table20. Exemplify GMAW-PP synergic programs

Wire material

Gas

Wire diameter

0.8

0.9

1.0

1.2

1.4

1.6

Aluminum AlSi

Ar

-

-

98

99

-

100

Aluminum AlMg

Ar

-

-

101

102

-

103

Note:

The list of available programs depends on the power source.

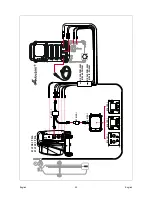

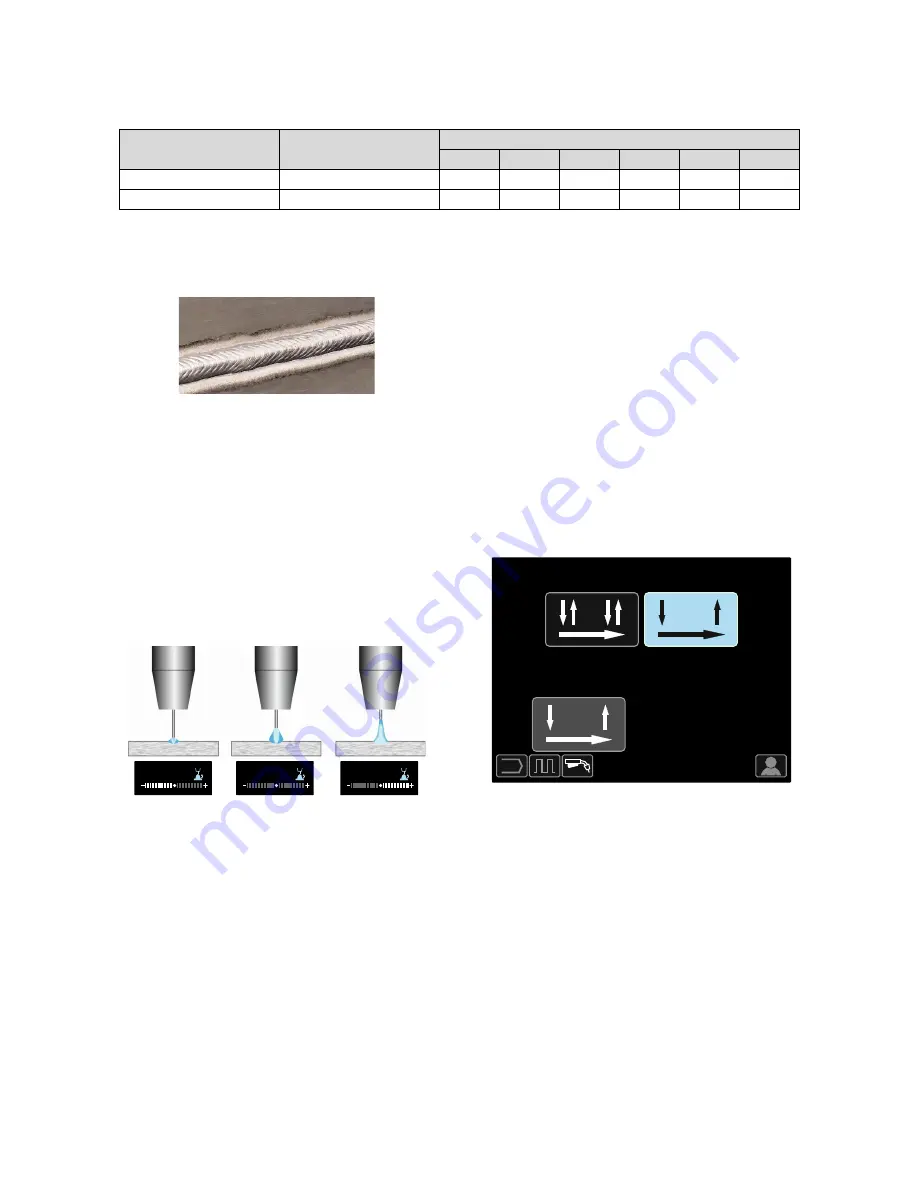

GMAW-PP (Pulse-On-Pulse

®

) process is used for

aluminum welding. Use it to make welds with a "stacked

dime" appearance, similar to GTAW welds (see

Figure 79).

Figure 79

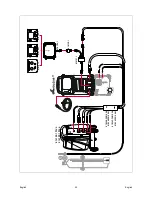

Wire Feed Speed [9] is the main control parameter. As

the Wire Feed Speed is adjusted, the power source

adjusts the waveform parameters to maintain good

welding characteristics. Each pulse sends a small

droplet of molten metal from the wire to the weld

puddle.

Trim [10] is used as a secondary control – the value of

parameter in the upper right side of display [26]. The

Trim setting adjusts the arc length. Trim is adjustable

from 0.50 to 1.50. 1.00 is the nominal setting.

Increasing the Trim value increases the arc length.

Decreasing the Trim value decreases the arc length.

1.00

0.50

1.50

Figure 80

When Trim is adjusted, the power source automatically

recalculates the voltage, current and time of each part

of the pulse waveform for the best result.

Additionally can manually set:

•

Burnback Time

•

Run-in WFS

•

Preflow Time/ Postflow Time

•

Spot Time

•

2-Step/4-Step

•

Polarity

•

Crater

•

Wave Control:

••••

Frequency

The 2-Step - 4-Step

changes the function of the gun’s

trigger.

•

2 Step trigger operation turns welding on and off in

direct response to the trigger. Welding process is

performed when the gun’s trigger is pulled.

•

4-Step mode allows to continue welding, when the

gun’s trigger is released. To stop welding, the gun’s

trigger is pulled again. 4-step mode facilitates to

making long welds.

Note:

4-Step does not work during Spot Welding.

M

Figure 81