English

English

40

Welding STT

®

Process

Table21. Exemplify STT

®

non-synergic programs

Wire material

Gas

Wire diameter

0.8

0.9

1.0

1.2

1.4

1.6

Steel

CO

2

-

304

306

308

-

-

Steel

ArMIX

-

305

307

309

-

-

Stainless

HeArCO

2

-

345

347

349

-

-

Stainless

ArMIX

-

344

346

348

-

-

Table 22. Exemplify STT

®

synergic programs

Wire material

Gas

Wire diameter

0.8

0.9

1.0

1.2

1.4

1.6

Steel

CO

2

-

324

326

328

-

-

Steel

ArMIX

-

325

327

329

-

-

Stainless

HeArCO

2

-

365

367

369

-

-

Stainless

ArMIX

-

364

366

368

-

-

Note:

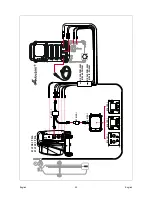

Note that STT

®

is available only with specially equipped Power Wave power sources, like the Power Wave

455M/STT

®

or the Power Wave S350 + STT

®

Module.

STT

®

(Surface Tension Transfer

®

) is a controlled GMAW

short circuit transfer process that uses current controls to

adjust the heat independent of the wire feed speed,

resulting in superior arc performance, good penetration,

low heat input control, reduced spatter and fumes.

The STT

®

process makes welds that require low heat

input much easier without overheating or burning

through, and distortion is minimized.

STT

®

is also ideal for:

••••

Open root welding

••••

Welding on thin materials

••••

Welding on parts with poor fit-up.

During STT

®

welding, sense lead has to be connected to

the workpiece.

Welding STT

®

in non-synergic mode

Manually can set:

•

Wire Feed Speed, WFS [9]

•

Burnback Time

•

Run-in WFS

•

Preflow Time/ Postflow Time

•

Spot Time

•

2-Step/4-Step

•

Crater

•

Wave Controls:

••••

Peak Current

••••

Background Current

••••

TailOut

••••

HOT START

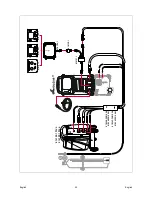

During the STT

®

welding in non-synergic mode, voltage

control is disabled.

125

A

22.5

V

1.0

Steel

CO2

min

m

5.71

306

A

Figure 84

Welding STT

®

in synergic mode

In synergic mode, the welding parameters are optimally

set to the Wire Feed Speed [9].

Wire Feed Speed controls the deposition rate.

Trim [10] is used as a secondary control – the value of

parameter in the upper right side of display [26]. The

Trim setting adjusts the arc length. Trim is adjustable

from 0.50 to 1.50. 1.00 is the nominal setting.

Additionally can manually set:

•

Burnback Time

•

Run-in WFS

•

Preflow Time/ Postflow Time

•

Spot Time

•

2-Step/4-Step

•

Crater

•

Wave Controls:

••••

UltimArc™

••••

HOT START.