D-4

MAINTENANCE

D-4

POWER-ARC 5500

GENERATOR/WELDER MAINTENANCE

STORAGE:

Store the POWER-ARC 5500 in clean,

dry, protected areas.

CLEANING:

Blow out the generator and controls

periodically with low pressure air. Do this at least

once a week in particularly dirty areas.

BRUSH REMOVAL AND REPLACEMENT:

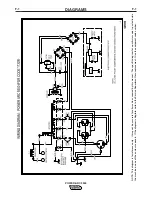

See

Figure D.5. It’s normal for the brushes and slip

rings to wear and darken slightly. Inspect the

brushes when a general overhaul is necessary.

Remove the brushes and clean the slip rings with

fine grit emery paper.

Do not attempt to polish slip rings while engine

is running.

To reinstall the brushes, press them upward and

slide a cable tie or wooden stick through the brush

holder tabs. Install the brush holder into the bear-

ing end bracket and secure with the screws previ-

ously removed. Remove the cable tie or wooden

stick and the brushes will seat onto the slip rings.

RECEPTACLES:

Keep the electrical receptacles in

good condition. Remove any dirt, oil, or other

debris from their surfaces and holes.

CABLE CONNECTIONS:

Check the welding cable

connections at the weld output terminals often. Be

sure that the connections are always tight.

NOTE:

Lincoln offers a rotor removal kit for any ser-

vice which requires removal of the rotor from the

engine. See the ACCESSORIES section for further

details.

Removal of engine/generator assembly from the

cradle can be achieved as follows:

• Remove the two 5/16-18 hex head cap screws

from the engine block via the access hole located

in the cradle cross support channel. Leave all

other engine mountings intact.

• Remove the two hex nuts from the isolator thread-

ed posts at the stator support bracket located

opposite the engine. Leave all other stator mount-

ings intact.

• With a jib hoist or crane, lift the unit upward and

remove loose cradle from engine/generator

assembly.

1

3

5

6

2

4

FIGURE D.5. – BRUSH REMOVAL AND REPLACEMENT

1. GENERATOR END BRACKET

2. BRUSH HOLDER ASSEMBLY

3. COVER

4. SCREWS (2)

5. BRUSHES

6. CABLE TIE

CAUTION