English

English

27

4-Step Trigger: Special Considerations

The response to the trigger with 4-step trigger active is dependent upon when the trigger is pulled/released and the

settings for START and CRATER.

Example 1.

Pull the trigger to start feed of wire. When arc is established the sequencer will remain in START until the trigger is

released. When the trigger is released, UPSLOPE begins. If trigger is pulled again during UPSLOPE and

CRATER/DOWNSLOPE is active, the feeder will begin the DOWNSLOPE, sloping down over the CRATER time,

regardless of when the trigger pull occurred.

If the CRATER/DOWNSLOPE state is disabled and the trigger is pulled during UPSLOPE, the sequencer will remain in

the UPSLOPE state and continue with the weld. If the fourth step (trigger release) occurs during UPSLOPE, the

sequencer will jump to the BURNBACK to end the weld.

Example 2:

Pull the trigger to start feed of wire. When arc is established the sequencer will remain in START until the trigger is

released. When the trigger is released, UPSLOPE begins and continues into WELD when the START timer is complete.

When the trigger is pulled again (step 3) and CRATER/DOWNSLOPE is active, DOWNSLOPE begins and continues

until the CRATER timer expires, at which time CRATER will be entered until the trigger is released.

While in DOWNSLOPE, if the trigger is released before the timer expires, the trigger will be ignored and the

DOWNSLOPE state will con-tinue until the timer expires, at which point CRATER state will be enabled, check for trigger,

and jump to BURNBACK since the trigger has been released.

While in the DOWNSLOPE state and the trigger is released and then pulled again, it will be ignored. During 4-Step

operation in DOWNS-LOPE, the trigger will always be ignored.

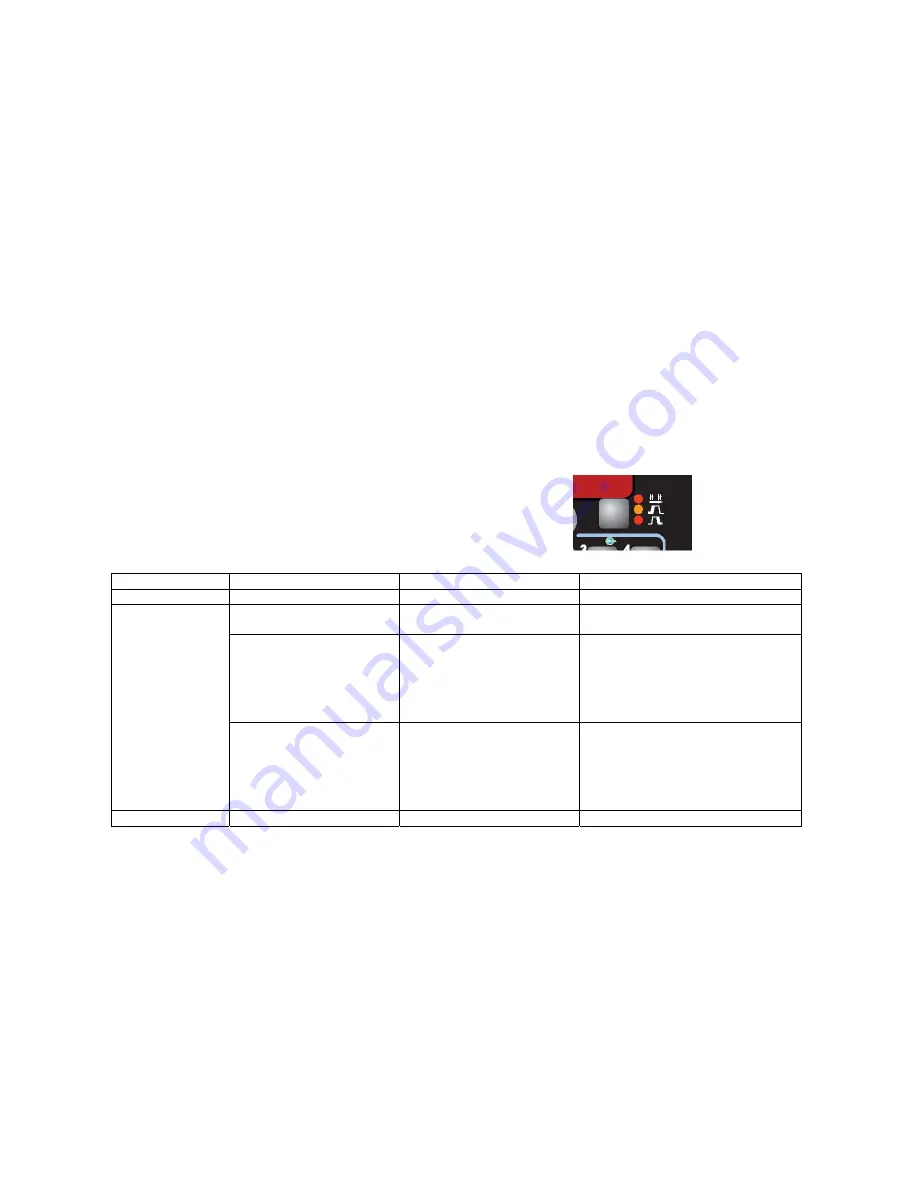

Start Options

The Start Options available depend upon the process and weld mode selected.

Process

Start Options

Effect / Range

Description

SMAW (Stick)

---

---

---

All GMAW (MIG)

and FCAW (Flux-

cored)

Preflow

Time

0 – 25.0

Seconds

---

Run-In WFS

Auto, OFF, 30 in/min to weld

WFS

Run-In sets the wire feed speed

from the time the trigger is pulled

until an arc is established or 2.5

seconds.

Use run-in for softer arc starts.

Start Time, WFS and Volts

0 – 10.0 seconds

The Start Procedure controls the

WFS and Volts for a specified time

at the beginning of the weld. During

the start time, the machine will ramp

up or down from the Start Procedure

to the preset Welding Procedure.

GTAW (TIG)

---

---

---