CONTROL CABLE CONNECTIONS

BETWEEN POWER SOURCE AND

WIREFEEDER

Connect the control cable between the power source

and wire feeder. The wire feeder connection on the

PowerWave AC/DC is located under the spring loaded

output cover, on the case front. The control cable is

keyed and polarized to prevent improper connect.

For convenience, the control cables can be routed

behind the left or right strain relief (under the spring

loaded output cover), along the channels of the Power

Wave, out the back of the channels, and then to the

wire feeder.

Excessive voltage drops at the work piece con-

nection often result in unsatisfactory pulse weld-

ing performance.

------------------------------------------------------------------------

CONTROL CABLE CONNECTIONS

BETWEEN POWER SOURCES RUN

IN PARALLEL

The connectors located on the rear of the machine are

used for synchronizing the operation of multiple

machines. To run machines in parallel connect the

control cable (K1795 series) between power sources

that are to run in parallel. The bottom (male) connec-

tor on the master connects to the top (female) connec-

tor on the slave. If needed the bottom connector on

the slave machine is then used to connect to another

slave machine. This connection scheme is duplicated

for any additional slaves.

CONTROL CABLE CONNECTIONS

BETWEEN A

POWER SOURCE

AND PHASE GENERATOR

If multiple arcs need to be synchronized an external

phase generator is required. The phase generator is

connected to all of the master machines. A control

cable (K1795 series) should be connected between

the phase generator and the top (female) connector

on the rear of the master machine.

CONTROL CABLE SPECIFICATIONS

It is recommended that genuine Lincoln control cables

be used at all times. Lincoln cables are specifically

designed for the communication and power needs of

the Power Wave / Power Feed system.

The use of non-standard cables, especially in

lengths greater than 25 feet, can lead to communi-

cation problems (system shutdowns), poor motor

acceleration (poor arc starting) and low wire dri-

ving force (wire feeding problems). Use the short-

est length of control cable possible. Do not coil

excess cable as this can cause communication

problems (system shutdowns).

------------------------------------------------------------------------

Lincoln control cables are copper 22 conductor cable

in a SO-type rubber jacket.

The K1795 series of control cables can be added in

series as needed. Do not exceed more than 100 feet

(30.5 m) total control cable length.

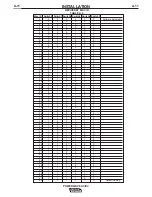

ETHERNET CONNECTIONS

The PowerWave is equipped with an Ethernet con-

nector, which is located under the spring loaded out-

put cover. All Ethernet cables external to either a con-

duit or an enclosure should be solid, shielded with a

drain, cat 5 cable. The drain should be grounded. Do

not use cat 5+, cat 5E, cat 6 or stranded cable. If con-

nection failure during welding persists reroute cables

away from any other cables that carry current or other

devices that would create a magnetic field. See Figure

A.4a.

FIGURE A.4a

CAUTION

CAUTION

A-8

INSTALLATION

POWER WAVE AC/DC

A-8

POWER WAVE

POWER WAVE

POWER WAVE

POWER WAVE

POWER WAVE

PHASE

GENERATOR

CAT 5 CABLE

SOLID, SHIELDED,

WITH A DRAIN

(MAX LENGTH =

3 METERS)

JUNCTION BOX

CONDUIT WITH CAT 5 UTP CABLE

ENVIRONMENTAL

ENCLOSURE

ETHERNET SWITCH

PATCH PANEL

POWER WAVE ETHERNET LAYOUT SETUP

- MAX TOTAL CABLE LENGTH IS 70 METERS

(FROM POWER WAVE TO PATCH PANEL)

- SHIELDED CABLE SHOULD BE GROUNDED

AT JUNCTION BOX

- REFER TO ISO / IEC 11801 FOR SPECIFICATIONS

Summary of Contents for POWER WAVE AC/DC

Page 19: ...A 12 INSTALLATION POWER WAVE AC DC A 12 Bank S3 and S4...

Page 43: ...NOTES POWER WAVE AC DC...

Page 44: ...NOTES POWER WAVE AC DC...