THEORY OF OPERATION

E-4

E-4

SAE-400 SEVERE DUTY

Return to Section

T

OC

Return to Section

T

OC

Return to Section

T

OC

Return to Section

T

OC

Return to Master

T

OC

Return to Master

T

OC

Return to Master

T

OC

Return to Master

T

OC

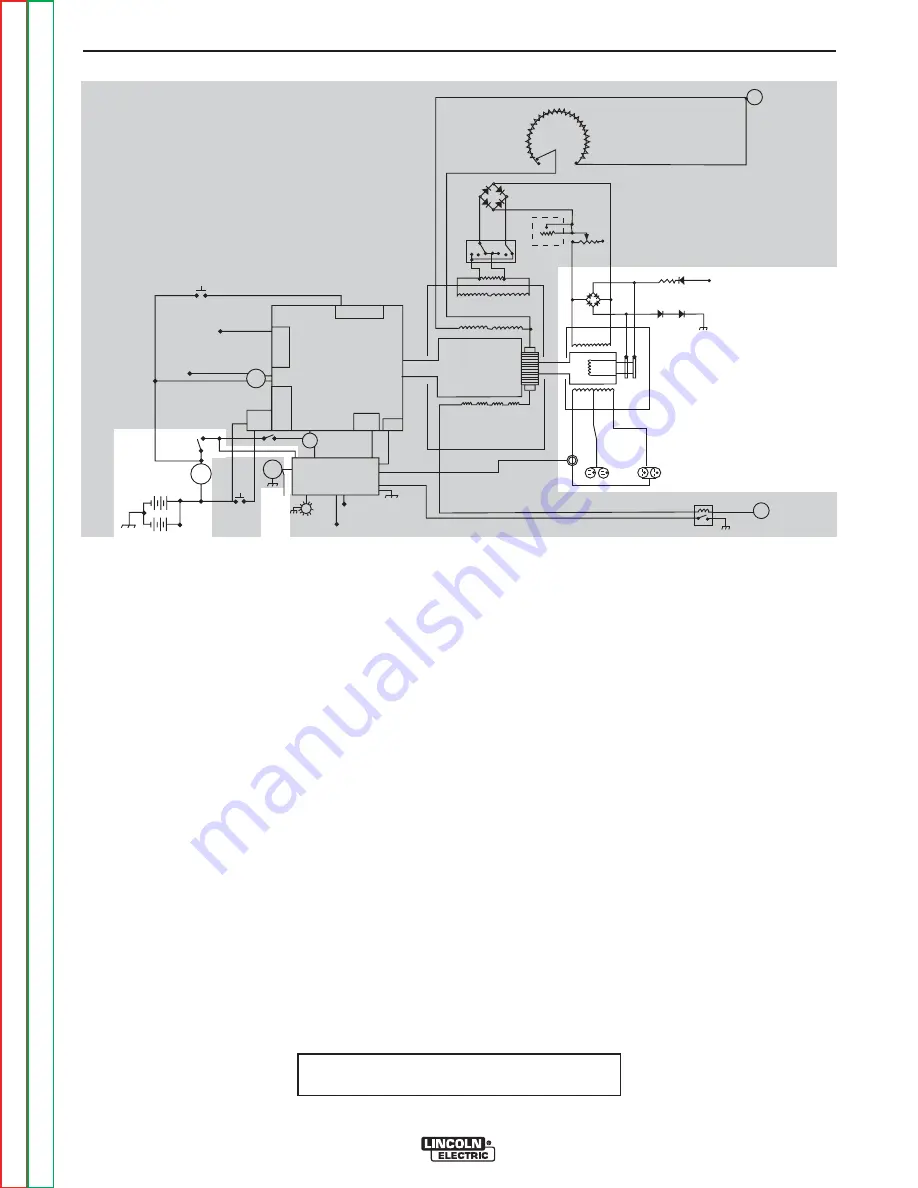

EXCITER/AUXILIARY ALTERNATOR

OPERATION

The exciter alternator is the smaller power generator

that is located at the end of the main welding genera-

tor. It provides power to energize the rotor, the shunt

fields of the main welding generator and about 3 KVA

of 120/230 volts, 60 Hz. for auxiliary power.

Flashing:

The exciter alternator requires that DC power be

applied to the slip rings to start the power generation

process. This DC power is often referred to as

“Flashing” voltage, and originates at the battery. This

voltage is applied through the Idler/Engine Protection

PC Board, whenever the fuel solenoid is open and the

hour meter is running.

The flashing current passes through a blocking diode

and current limiting resistor before being applied to the

rotor field winding through the positive brush and slip

ring. The current then passes out of the negative slip

ring and brush, through two diodes, and back to the

battery through a chassis ground connection.

FIGURE E.2 - GENERAL DESCRIPTION

Building output:

The flashing current produces a weak magnetic field in

the rotor, which is coupled to the now running engine.

This rotating magnetic field begins to generate AC out-

put from all of the stator windings. Output from the

exciter winding is rectified by a diode bridge, and then

fed back into the rotating field winding, through the

brushes, making the magnetic field stronger. This

stronger magnetic field then produces higher voltage

from the stator windings, which feeds back to the rotor,

making its magnetic field even stronger.

This process of strengthening the magnetic field

through feedback from the exciter winding continues to

increase the output of the alternator until the design

voltage is reached.

The field voltage is now considerably higher than the

flashing voltage that was used to start the generating

process. The diode in the flashing circuit now blocks

that higher field voltage from intruding into the 12VDC

battery system and the machine chassis.

(continued on next page)

DIESEL

ENGINE

THERMOSTAT

INJECTION

PUMP

SOLENOID

SYSTEM

THERMOSTART

BUTTON

IDLE SWITCH

IDLE

SOLENOID

IDLE / ENGINE

PROTECTION BOARD

TO IDLE / ENGINE

PROTECTION BOARD

RUN/STOP

SWITCH

S

T

A

R

T

E

R

TO IDLE/ENGINE

PROT. BOARD

OIL

PRESSURE

SWITCH

TEMP

SWITCH

STARTER

SOLENOID

AMMETER

START

BUTTON

ENGINE

FAULT

LIGHT

HOUR

METER

TO

FLASHING

RESISTOR

AND

DIODE

INTERPOLE COILS

GENERATOR

ARMATURE

SERIES COILS

SHUNT COILS

115 VAC

RECEPTACLES

230 VAC

RECEPTACLES

AUXILIARY

POWER

WINDINGS

EXCITER

WINDING

EXCITER

ROTOR

MIN

(OFF)

MAX

OUTPUT

CONTROL

ELECTRODE

TERMINAL

RESISTOR

POLARITY

SWITCH

REMOTE

RHEOSTAT

LOCAL

RHEOSTAT

(JOB SELECTOR)

TO HOUR METER

FLASHING

RESISTOR AND

DIODE

(+)

(+)

(-)

(-)

AC

AC

(-)

(+)

WORK

TERMINAL

TO ALTERNATOR

FLASH/SENSE

TO INJECTION

PUMP SOLENOID

NOTE: Unshaded areas of Block Logic

Diagram are the subject of discussion