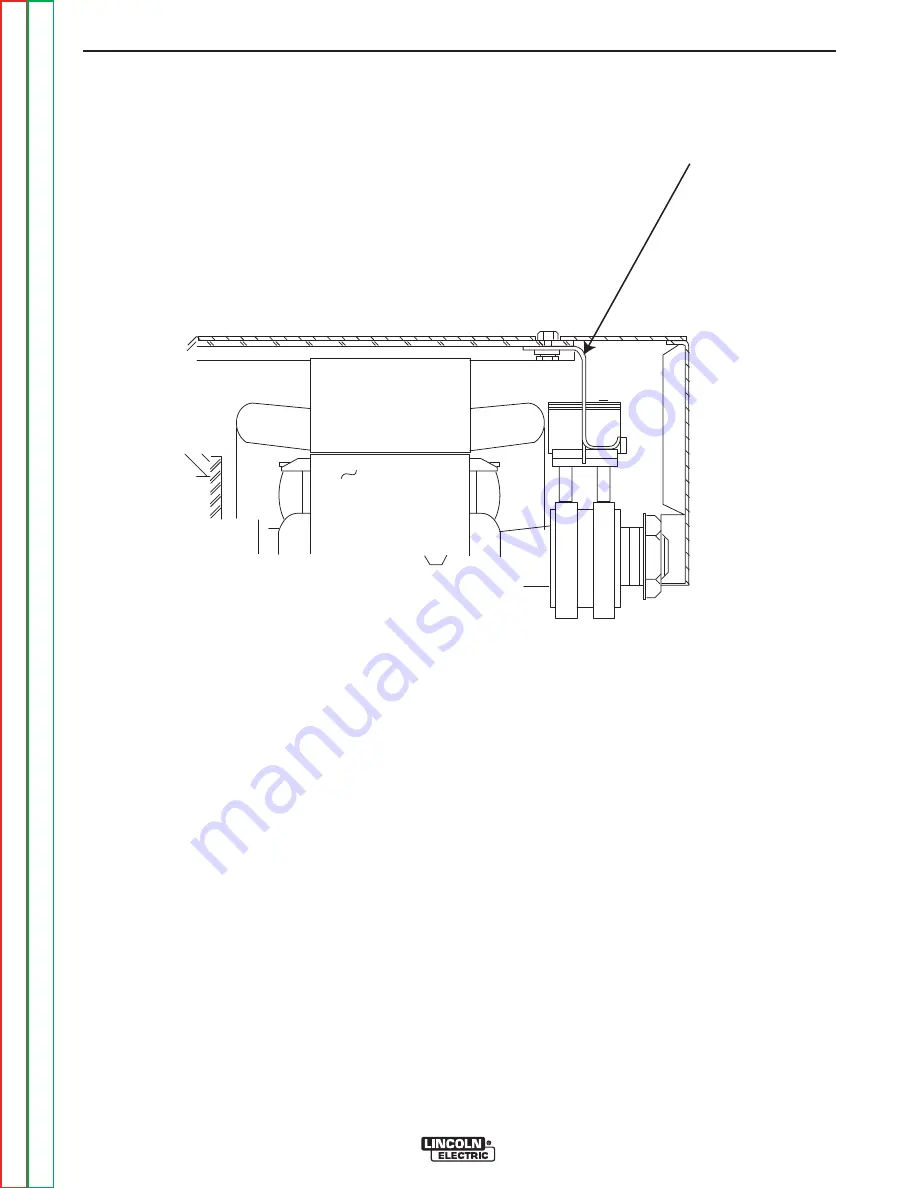

BRUSHES

FIGURE F.4 – BRUSH LOCATIONS

BRUSH AND SLIP RING SERVICE PROCEDURE

(Exciter / Auxiliary Power Alternator) (continued)

PROCEDURE (continued

5. Check for evidence of sticking brushes. Sticking

brushes will normally result in the slip rings being

pitted and discolored from excessive arcing.

Another sign of sticking brushes is instability or loss

of both weld and auxiliary output, but the machine

may begin to work properly, for a short time, after

being jarred or moved.

6. If there is any evidence that the brushes may have

been sticking in the brush holders, a new brush

holder and brush assembly should be installed.

Cleaning slip rings:

In the event that the slip rings have become dirty, dis-

colored or mildly pitted, it will be necessary to clean

them, using very fine (500 or 600 grit) emery cloth, or a

220 or 320 grit commutator stone.

CAUTION:

Commutator stones should only be used by

experienced technicians who have the

knowledge and equipment necessary to

use them safely.

Seating brushes:

If brushes have been replaced, repositioned, or are not

making full contact with the slip rings, it will be neces-

sary to re-seat them. This can be done by placing a

strip of 180 grit sandpaper between the slip rings and

the brushes, with the abrasive side against the brush-

es. Pull the sandpaper strip around the circumference

of the slip rings in the direction of rotor rotation only.

Repeat this procedure until the surface of each brush

is in full contact with its matching slip ring.

Use low pressure compressed air to thoroughly blow

the carbon, commutator stone, and sandpaper dust

from the machine before operating.

Securely connect the leads to the brush terminals (see

wiring Diagram) and replace the alternator cover if test-

ing and service is complete.

TROUBLESHOOTING AND REPAIR

F-27

F-27

SAE-400 SEVERE DUTY

Return to Section

T

OC

Return to Section

T

OC

Return to Section

T

OC

Return to Section

T

OC

Return to Master

T

OC

Return to Master

T

OC

Return to Master

T

OC

Return to Master

T

OC