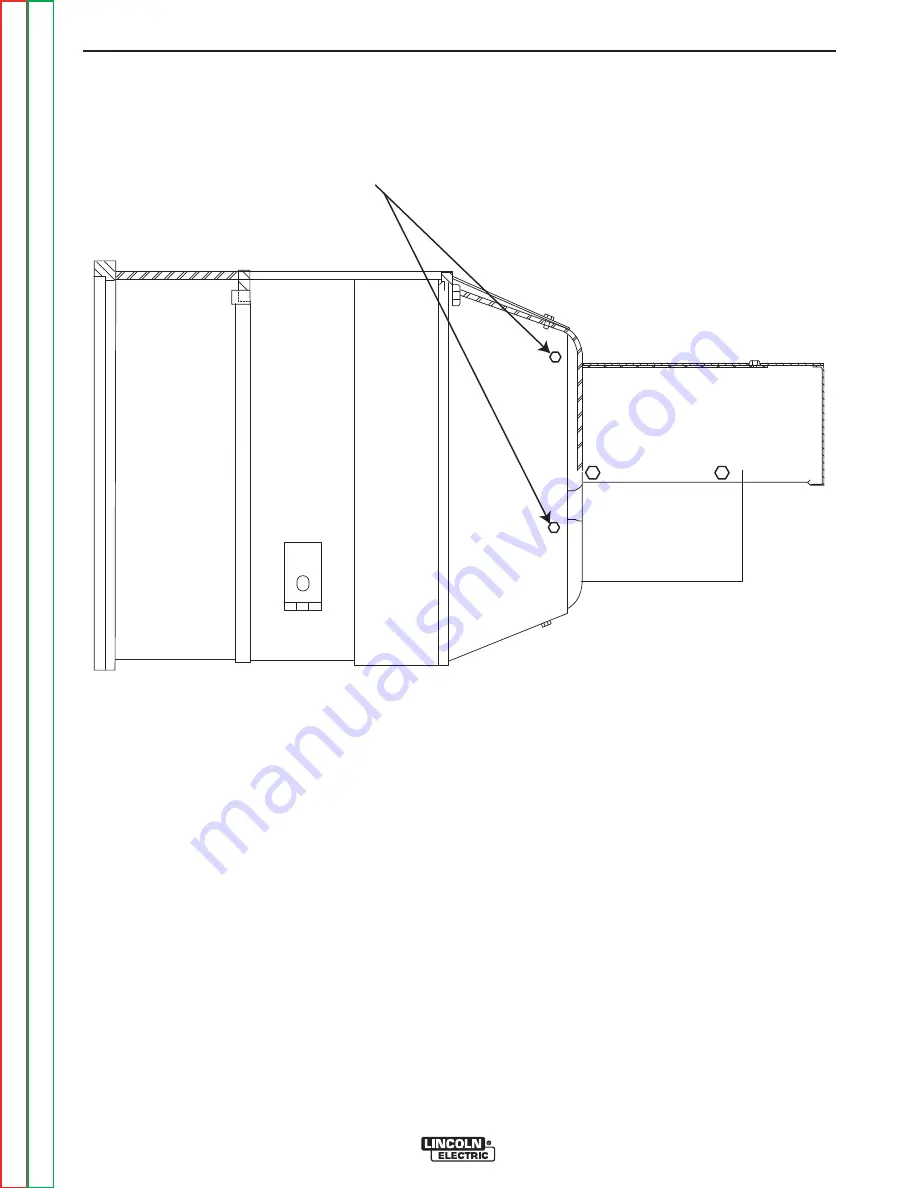

GENERATOR COVER

FOUR SCREWS TOTAL

FIGURE F.15 – GENERATOR COVER SCREW LOCATIONS

WELDING GENERATOR BRUSH AND COMMUTATOR INSPECTION AND

SERVICE (continued)

PROCEDURE

1. Shut off the engine.

2. Open either, or both of the doors on the control

panel end of the SAE-400 machine.

WARNING:

Secure the doors in the open position

using the door restraint system. If the

machine does not have a door restraint

system, remove the doors or securely

restrain them to prevent them from falling

closed.

3. Disconnect the negative battery cable.

4. Remove the sheet metal covers protecting the

welder generator brushes. See Figure F.15.

TROUBLESHOOTING AND REPAIR

F-44

F-44

SAE-400 SEVERE DUTY

Return to Section

T

OC

Return to Section

T

OC

Return to Section

T

OC

Return to Section

T

OC

Return to Master

T

OC

Return to Master

T

OC

Return to Master

T

OC

Return to Master

T

OC