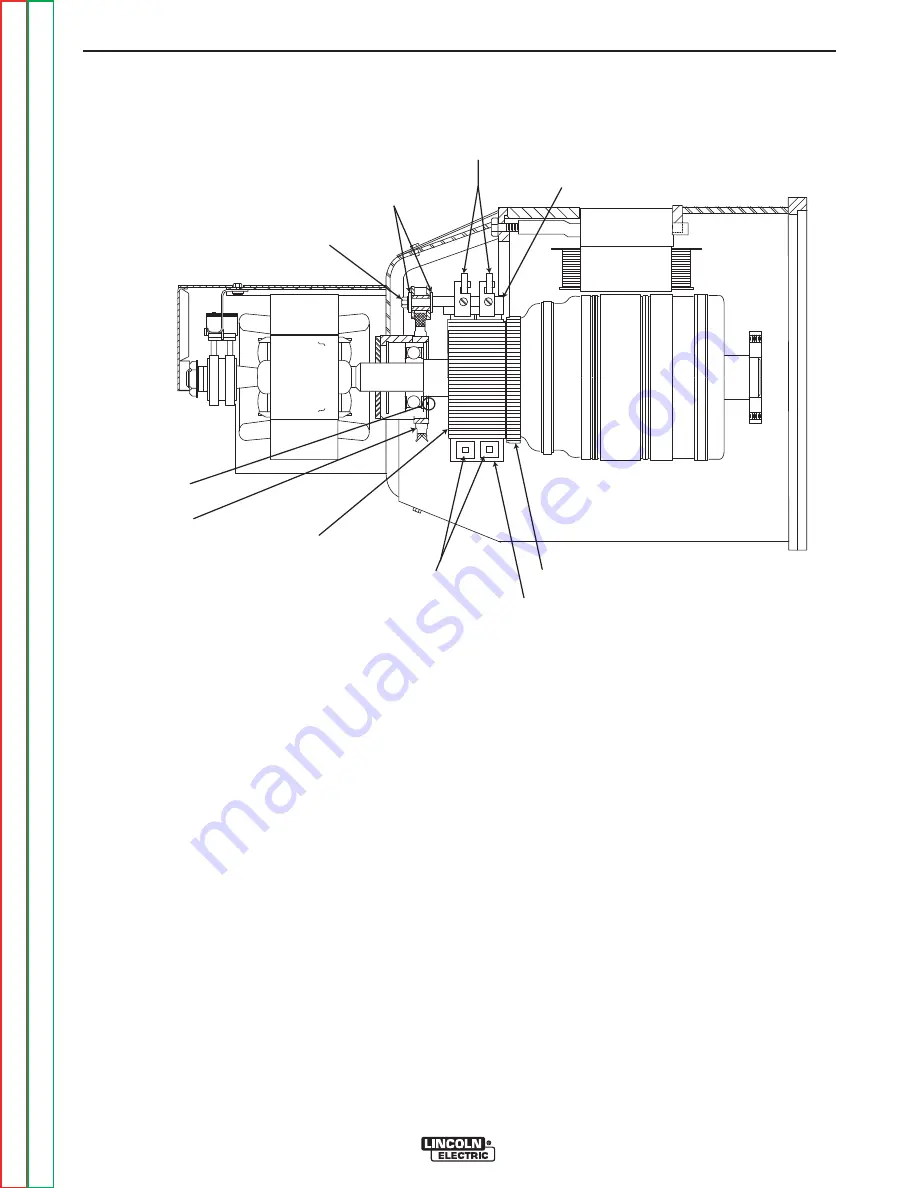

ARMATURE

COMMUTATOR

SPRINGS

BRUSH HOLDER PLATE

BRUSHES

BRUSH RETAINER

BRUSH HOLDER

INSULATORS

MOUNTING SCREW

DRILL MARK

ROCKER

FIGURE F.16 – GENERATOR COMPONENTS

WELDING GENERATOR BRUSH AND COMMUTATOR INSPECTION AND

SERVICE (continued)

PROCEDURE

5. Examine the Commutator.

Normal appearance:

The commutator should appear smooth, and have an

even brown color where the brushes ride.

Blackened Commutator:

A commutator that appears to have an even black color

all around may indicate a grounded armature, shorted

weld circuit, a serious overload condition, or out-of-

adjustment rocker. It could also indicate the use of

poor quality brushes, or brushes that have been conta-

minated with oil or some other foreign substance.

•

Check the rocker position. Be certain that it is

aligned with or very close to the factory drill mark.

See Figure 16. IMPORTANT: If the rocker position

requires adjustment, do not over tighten the rocker

clamping screw. This screw should be tightened to

a torque of 70 to 75 Inch-Lbs. Over tightening can

destroy the rocker.

•

Perform the

Weld Circuit Ground and Short

Circuit Test

.

•

If the weld circuit is not grounded or shorted, and

poor brush quality or contamination is suspected,

replace the brushes and seat them with a commu-

tator stone or sand paper.

•

If brush quality or contamination is not suspected,

clean the commutator by lightly stoning the sur-

face.

CAUTION:

Stoning the commutator involves pressing

an abrasive stone against a spinning com-

mutator. This procedure can be haz-

ardous if done without proper training,

tools and protective equipment. Consult

the commutator stone manufacturer’s

instructions before attempting this proce-

dure.

TROUBLESHOOTING AND REPAIR

F-45

F-45

SAE-400 SEVERE DUTY

Return to Section

T

OC

Return to Section

T

OC

Return to Section

T

OC

Return to Section

T

OC

Return to Master

T

OC

Return to Master

T

OC

Return to Master

T

OC

Return to Master

T

OC