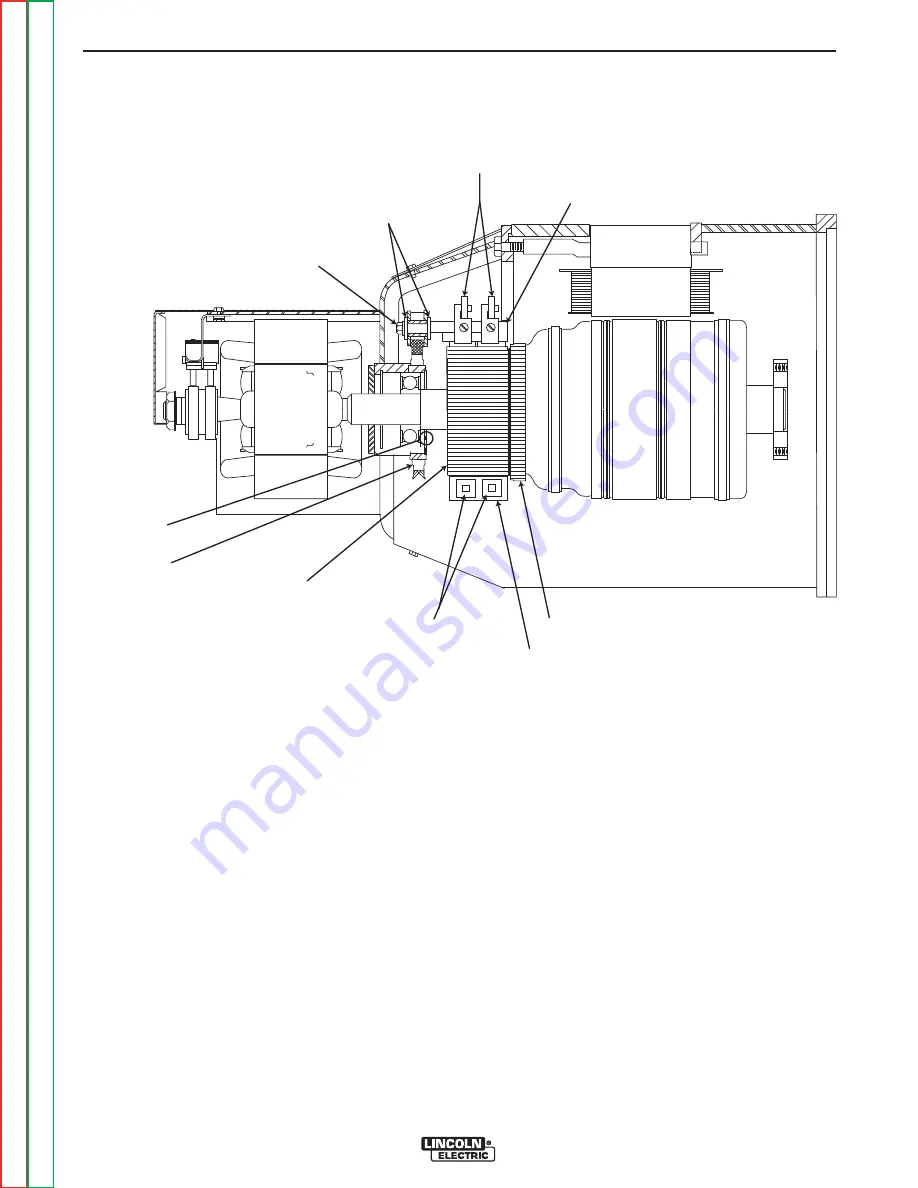

ARMATURE

COMMUTATOR

SPRINGS

BRUSH HOLDER PLATE

BRUSHES

BRUSH RETAINER

BRUSH HOLDER

INSULATORS

MOUNTING SCREW

DRILL MARK

ROCKER

FIGURE F.18 – ROCKER W/MARKS

ROCKER ADJUSTMENT PROCEDURE (continued)

PROCEDURE

The factory set point drill marks:

1. When the rocker is set for the first time at the facto-

ry, a 1/8” drill is used to mark the position of both the

rocker and the exciter bracket. See Figure F.18

If a machine is not operating within the specified limits,

and nothing else appears to be faulty, the rocker posi-

tion should be checked. If the drill marks are not

aligned, the rocker and/or the exciter bracket should be

reset to the original factory position.

If it has been determined that a rocker adjustment is

necessary on an unaltered machine; the rocker should

only be moved in very small increments, and the total

movement should be no more than ½ the diameter of

the drill mark.

Setting the Rocker -

if the factory drill mark is miss-

ing or invalid due to component replacement.

IMPORTANT:

The following procedures should only be

attempted if all the other systems have

been thoroughly checked and are func-

tioning normally.

A tachometer will be required for this phase of the test.

See the

Engine RPM Adjustment Tes

t for details

about measuring engine RPM.

TROUBLESHOOTING AND REPAIR

F-56

F-56

SAE-400 SEVERE DUTY

Return to Section

T

OC

Return to Section

T

OC

Return to Section

T

OC

Return to Section

T

OC

Return to Master

T

OC

Return to Master

T

OC

Return to Master

T

OC

Return to Master

T

OC