A-2

INSTALLATION

SAM400 & 650

A-2

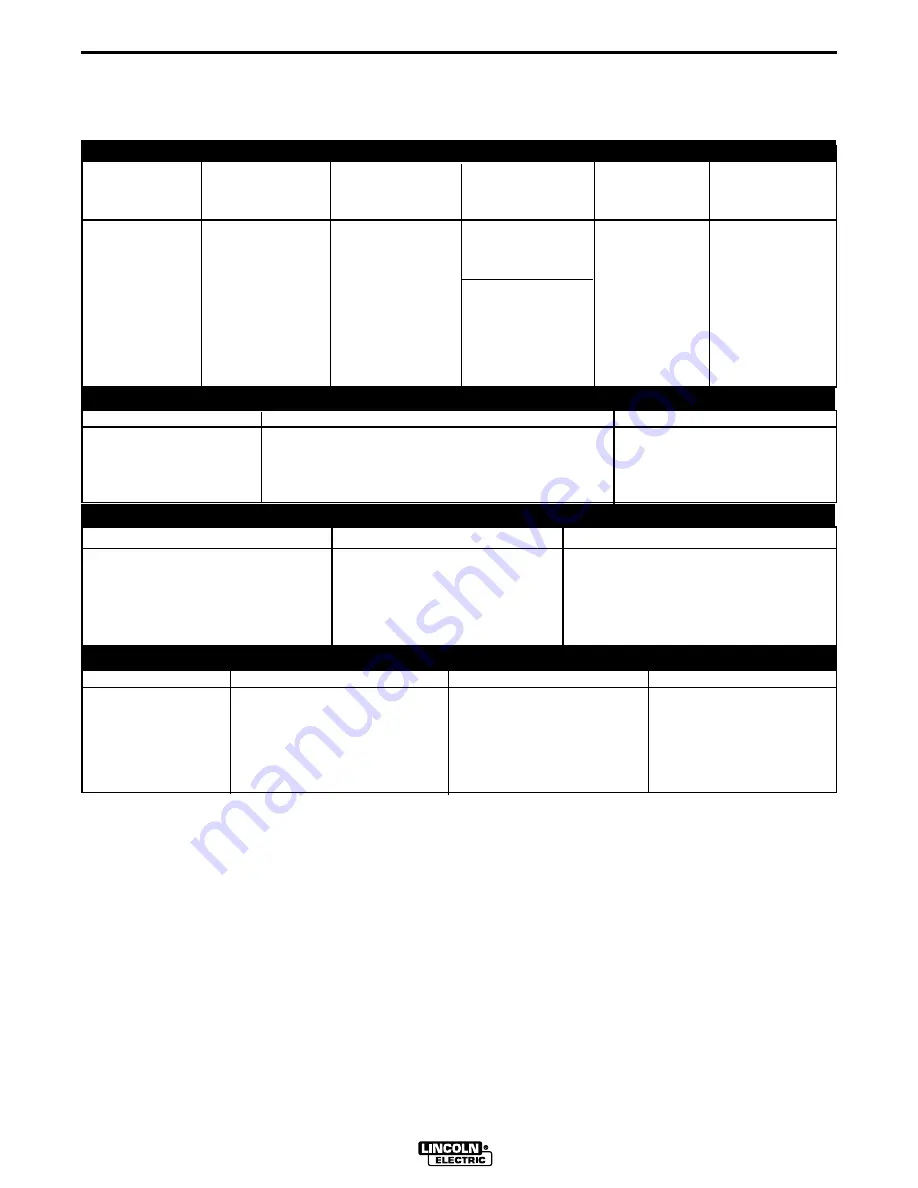

TECHNICAL SPECIFICATIONS - SAM650

Make/Model

Description

Speed (RPM)

Displacement

Starting

Capacities

System

Perkins

6 cylinder

High Idle 1790

365 cu. in

12VDC batteries

Fuel: 22.5 gal.

1006-6 Diesel

93 HP @

Low Idle 1200

(5.98 L)

(2) & Starter

85.1 L

Engine

1730 RPM

Full Load 1750

Bore x Stroke

Oil: 14.0 Qts.

13.24 L

3.937” x 5.00”

(100mm x 127mm)

Coolant: 5.5 gal.

20.8 L

INPUT - DIESEL ENGINE

RATED OUTPUT - WELDER

HEIGHT

WIDTH

DEPTH

WEIGHT

56.7 in.

27.12 in.

88.75 in.

2800 lbs.

1440.2 mm

688.9 mm

2254.2 mm

1270.1 kg

OUTPUT - WELDER AND GENERATOR

Duty Cycle

Welding Output

Volts at Rated Amps

80% (NEMA)

650 Amps

44 volts

60%(NEMA)

725 Amps

44 volts

80%(Lincoln Plus)

650 Amps

50 volts

60%(Lincoln Plus)

725 Amps

50 volts

Welding Range

Open Circuit Voltage

Auxiliary Power

80 - 815 Amps

18 - 50 OCV

120/240 VAC

CV Current Range

(excluding hot start voltage)

2kVA, 60 Hz.

80 - 815

45 - 90 OCV

100% Duty Cycle

VV Current Range

PHYSICAL DIMENSIONS