B-8

SP-135 PLUS

B-8

LEARNING TO WELD

LEARNING TO WELD

No one can learn to weld simply by reading about it.

Skill comes only with practice. The following pages will

help the inexperienced operator to understand weld-

ing and develop this skill. For more detailed informa-

tion, order a copy of

“

New Lessons in Arc Welding

”

listed at the end of this manual.

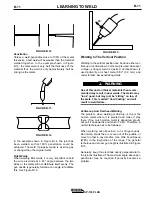

THE ARC-WELDING CIRCUIT

The operator

’

s knowledge of arc welding must go

beyond the arc itself. The operator must know how to

control the arc, and this requires a knowledge of the

welding circuit and the equipment that provides the

electric current used in the arc. Figure B.7 illustrates

the welding circuit for a typical welding machine. The

circuit begins where the gun cable is attached to the

welding machine. Current flows through the gun cable,

gun, and contact tip, to the wire and across the arc.

On the work side of the arc, current flows through the

base metal to the work cable and back to the welding

machine. This circuit must be complete for the current

to flow.

This machine

’

s welding circuit has a voltage output of

33 volts DC maximum. This voltage is quite low and is

only present when the gun trigger is depressed.

To weld, the work clamp must be tightly connected to

clean base metal. Remove paint, rust, dirt or oil as

necessary and connect the work clamp as close as

possible to the area you wish to weld. This helps pre-

vent current from going through an unwanted path.

Avoid allowing the welding circuit to pass through

hinges, bearings, electronic components, or similar

devices that can be damaged. See Figure B.8. Always

disconnect electrical devices before welding upon

them.

Fumes and slag generated from

Innershield type electrodes recom-

mended for use with this welding

machine can be toxic.

•

Avoid contact with eyes and skin.

•

Do not take internally.

•

Keep out of reach of children.

•

Follow all safety precautions

found in this operating manual.

The gun and cable assembly is held by the operator

who guides the automatically fed wire along the joint,

maintaining a contact tip to work distance of about 3/8

to 1/2 inch (10

–

12 mm). This is called electrical stick-

out. This electrical stickout (ESO) must be properly

maintained by the operator. The electric arc is made in

the gap between the work and the tip end of a small

diameter wire. When the power source is properly set,

the arc gap is maintained automatically.

Arc welding is a manual skill requiring a steady hand,

good physical condition, and good eyesight. The oper-

ator controls the welding arc, and therefore, the quality

of the weld made.

THE SELF-SHIELDED FCAW WELDING

ARC

Figure B.9 illustrates the action taking place in the self

shielded FCAW (Innershield) welding arc. It closely

resembles what is actually seen while welding.

FIGURE B.9

WARNING

FIGURE B.8

Electronic Components

Hinges

Bearings

Burning of core

materials inside wire

electrode results in

shield of gas.

Arc Stream

Cored Wire

Protective Slag

Weld Metal

Summary of Contents for SP-135 PLUS IM725

Page 32: ...B 19 B 19 APPLICATION CHART SP 135 PLUS ...

Page 44: ...SP 135 PLUS NOTES ...