B-17

SP-170T

B-17

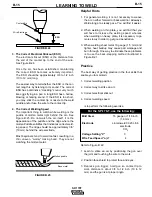

LEARNING TO WELD

Proper Gun Handling

Most feeding problems are caused by improper han-

dling of the gun cable or electrodes.

1. Do not kink or pull the gun around sharp corners

2. Keep the gun cable as straight as practical when

welding.

3. Do not allow dolly wheels or trucks to run over the

cables.

4. Keep the cable clean.

5. Innershield electrode has proper surface lubrica-

tion. Use only clean, rust-free electrode.

6. Replace contact tip when it becomes worn or the

end is fused or deformed.

Summary of Contents for SP-170T

Page 31: ...B 18 SP 170T B 18 APPLICATION CHART ...

Page 44: ...SP 170T NOTES ...