Spirit II User’s Manual

Section 6: Maintenance &Troubleshooting

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

6-13

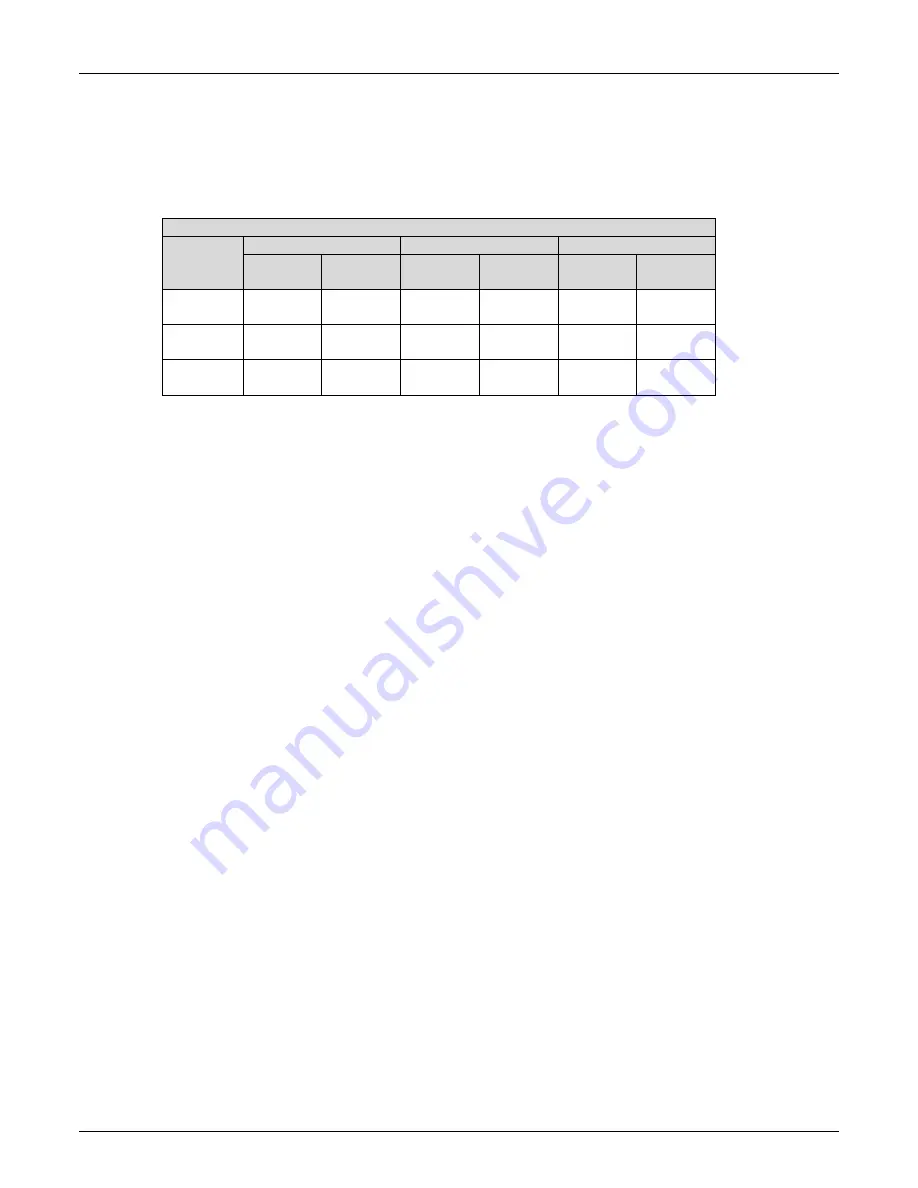

9. With a start signal applied, check for the proper DC voltage (refer to TABLE 1) at the

output terminal block between Electrode and Work, which is located on the left side

of the unit.

If the proper DC voltage is present, the chopper is working properly.

TABLE 1

Chopper 1

Chopper 2

Chopper 3

3 Phase

AC

OCV

(DC)

3 Phase

AC

OCV

(DC)

3 Phase

AC

OCV

(DC)

Spirit II

400 Amp

255

370

255

370

255

370

Spirit II

275 Amp

225

325

225

325

N/A

N/A

Spirit II

150 Amp

208

300

N/A

N/A

N/A

N/A

10. If the proper DC voltage is not present at the output terminal block, check the 200

amp fuse F9 (chopper 1), fuse F10 (chopper 2) or fuse F11 (chopper 3) located on

the bottom right of the output bus bars.

If the fuse is open, replace chopper and fuse.

11. If the fuse(s) is good, check if the chopper PWM LED illuminates when a start signal

is applied:

a) check D24 on the DSP PCB – If D24 doesn’t illuminate, replace DSP PCB.

b) check D2 on the chopper PCB – If D2 doesn’t illuminate green, go to step 12.

12. Check PCB power to the chopper from the DSP:

a) Push the OFF Button.

b) Disconnect the J1 plug from the chopper PCB.

c) Leave the OFF Button pushed in.

d) With a digital voltmeter, measure the following voltages on the J1 plug:

J1-5 (ground) to J1-1

+15vdc Supply

J1-5 (ground) to J1-2

+5vdc Supply

J1-5 (ground) to J1-3

+5vdc (PWM Signal)

If ALL of the voltages are present, replace chopper. If any of the voltages are not

present, go to step 13: