Retur

n to Section TOC

Retur

n to Section TOC

Retur

n to Section TOC

Retur

n to Section TOC

Retur

n to Master TOC

Retur

n to Master TOC

Retur

n to Master TOC

Retur

n to Master TOC

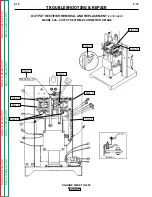

TROUBLESHOOTING & REPAIR

F-85

F-85

SQUARE WAVE TIG 355

RETEST AFTER REPAIR

(continued)

OUTPUT CURRENT RANGE

2 - 400 Amps AC and DC

RECOMMENDED METERS FOR MACHINE OUTPUT TESTS

VOLTMETER:

AC and DC True RMS Meter – Fluke 8922A or equivalent

AMMETER:

Columbia Type AX AC or DC Tong Ammeter

IMPORTANT: IF OTHER TYPE METERS ARE USED RESULTS MAY NOT BE ACCURATE

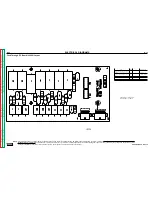

MAIN TRANSFORMER SECONDARY VOLTAGES (SEE FIGURE F32)

Test Points

Voltages

X1 to X2

84 to 89VAC

X3 to X4

117 to 125VAC

X5 to X6

22 to 24VAC

X2 to X7

77 to 81VAC

FIGURE F32. – TRANSFORMER LEAD TEST POINTS

X1

X7

X3

X4

X5

X6

X2