At Maximum, the arc will be more forceful and less

prone to sticking but will produce more spatter.

12. PREFLOW

This control adjusts the amount of time the gas

and water valves are open before the arc starts. It

is adjustable from 0 to 10 seconds.

The Preflow time occurs only if the valves were

closed (no gas flow) when the Arc Start switch or

Amptrol was pressed. If a new weld is started

while the gas valve is still on during the Afterflow

time of a previous weld, the Preflow time is

bypassed since gas shielding is already present.

This allows new welds to start immediately with no

preflow delay.

Note that since the arc cannot start during the

Preflow time, a long Preflow setting can cause

complaints about arc starting. In general, a

Preflow time of 0.5 seconds is satisfactory for

most applications.

13. SPOT CONTROLS

Spot Switch — A two-position toggle switch:

Recommended for use in the 2-step Arc Start

Switch mode only.

ON: Spot Time control is active. Once the arc is

established, the Spot time begins. At the end of

the Spot time (or if the Arc Start switch/Amptrol is

released sooner), the arc stops. (If Crater Fill [Item

16] is on, downslope begins.)

OFF: Locks out the Spot Time control.

Spot Time Control: Not active if the Spot switch

is off. Adjusts weld time from 0.1 to 5 seconds.

Weld time is the time from when the arc is fully

established until the arc is turned off (or when

Crater Fill downslope is started). The Arc Start

switch or Amptrol must be held down during the

Spot time; if it is released before the end of the

Spot time, the arc will be turned off (or Crater Fill

started).

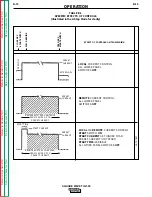

14. START CONTROLS

Start Switch — A two-position toggle switch:

ON: Start Current control is active. At the begin-

ning of the weld, current will be the value preset by

the Start Current control. Th position of the

Amptrol has no effect on this current.

OFF: Locks out Start Current and Time controls.

Start Current Display Pushbutton

Press and hold in this pushbutton to display the

Start Current preset by the Start Current control.

(The Volts/Amps switch (Item 7) must be in the

“AMPS” position to read preset current.)

Start Current Control

Locked out if the Start switch is off.

Presets the current that will be provided at the

start of the weld. The current can be preset from

2 to 400 amps. The position of the amptrol has no

effect on the initial current. The present Start

Current is displayed on the Ammeter when the

pushbutton is pressed before welding.

A “hot” start is used to quickly heat the tungsten

and work, usually on DC TIG welding. Set the

Start Current higher than what the welding current

will be. After the time is set on the Start Time con-

trol, the current will step down to the current set

and controlled by the Peak Current control (Item 6)

and the Amptrol.

A “soft” start is used to preheat the tungsten and

work, usually on AC TIG welding. Set the Start

Current lower than what the welding current will

be. The arc will establish at the Start Current and

then ramp up to the current set and controlled by

the Peak Current control (Item 6) and the Amptrol.

The time to get up to welding current is set by the

Start Time control. During the ramp up, the

Amptrol will affect the current that the ramp is

going toward and therefore the rate at which the

current increases.

Start Time Control

Locked out if the Start switch is off. Adjusts the

Start Time from approximately 0.1 to 10 seconds.

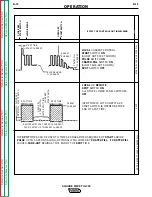

15. PULSE CONTROLS

Pulse Switch — A two-position toggle switch:

ON: Pulsing will begin as soon as an arc is estab-

lished and will continue until the weld is complet-

ed. If you are using Start Controls, pulsing begins

after the Start Current. If you are using Crater Fill,

pulsing will continue during the downslope period.

OFF: Locks out Pulse controls.

Pulses per Second Control — Controls the num-

ber of pulses per second from approximately 0.1

to 10 pps. 0.1 pulses per second is slow pulsing

(one pulse every 10 seconds); 10 pulses per sec-

ond is fast pulsing.

Background % Peak Current Control —

Controls the background (low pulse) current from

zero to 100% of the peak current set and con-

trolled by the Peak Current control (Item 6) and the

Amptrol.

OPERATION

B-8

B-8

SQUARE WAVE TIG 355

Retur

n to Section TOC

Retur

n to Section TOC

Retur

n to Section TOC

Retur

n to Section TOC

Retur

n to Master TOC

Retur

n to Master TOC

Retur

n to Master TOC

Retur

n to Master TOC